Build Your Own LumiBar-50 Plug & Play 50cm White LED Strip, Made in Germany, Nichia/Cree/Samsung/Seoul LEDs, 12/24/48V (up to 10000lm/m)

Use this specialized form to order your custom LumiBar-50 LED strip.

- More details below

- Terms & Conditions apply

- Information with * is required.

Build Your Own LumiBar-50 Nichia LED Strip

- LumiBar-50 can be equipped with 30-120 x Mid-Power Nichia 757 LEDs from Japan, with the highest performance on the market

- 500mm long LED strip, 5-20mm wide

- With optional versatile and easy-to-use plug-and-play connection system

- CRI options: 70, 80, 90, 95, 99

- Color temperature options: 1800K to 7800K

- Special Nichia technology options: Optisolis, Vitasolis, H6, HPS, Rs060 Hortisolis, Rs030 Fresh Food Shops, Rs020 Meat Shops (at 5000K)

- 12/24V/48VDC constant voltage

Build Your Own LumiBar-50 Plug & Play 50cm White LED Strip, Made in Germany, Nichia/Cree/Samsung/Seoul LEDs, 12/24/48V (up to 10000lm/m)

The LumiBar-50 Nichia LED strips are versatile and easy to use, ideal for a wide range of applications including commercial, industrial, general lighting, decorative lighting, exhibition stand construction, or task lighting. The available plug-fit system or connectors allows the strips to be connected into long light strips without soldering, with evenly spaced LEDs that can be split to light even tight spaces.

LumiBar-50 is designed to use the Nichia 757 Series Mid-Power LEDs, a huge market success due to their highest luminous efficacy (222 lm/w), small size (3030 package), extreme lifetime (more than 100,000 hours) and high versatility. Being able to equip the LumiBar-50 with the complete selection of Nichia 757 LEDs, with CRI 70, 80, 90, 95 or 98 and color temperature from 1800K to 6500K, you will be empowered to create the perfect product for your application.

The available specifications for customization related to LED density and width allow the LumiBar-50 to meet the majority of requirements for linear lighting applications.

Made in Germany, the Lumibar-50 LED strip is a professional product designed for long-term use, with a 5-year warranty.

Custom LED Solutions: Tailored Lighting Excellence

Don't settle for generic LED solutions when our customization service can match your unique needs, avoiding the compromises associated with off-the-shelf products. With over 20 years of industry expertise, we manufacture innovative, quality, and high-performance LED solutions in Germany, tailored to your specifications.

Simplified Customization Process & Professional Support

We make designing LED lighting easy with this specialized process to build your own LED strips 50 cm long and up to 20mm wide, in white, with options covering size, specifications, and electrical characteristics.

Starting a custom LED project might seem challenging, but we are here to help, offering comprehensive support for selecting LEDs, drive modes, controls, thermal management, and connectivity.

Begin Your Custom LED Project

Ready to transform your vision into reality with the perfect LED strip? Order now and let us illuminate your path to innovation, ensuring your project shines brighter than ever.

Custom LumiBar-50 LED Strip Order Process explained & Technical details:

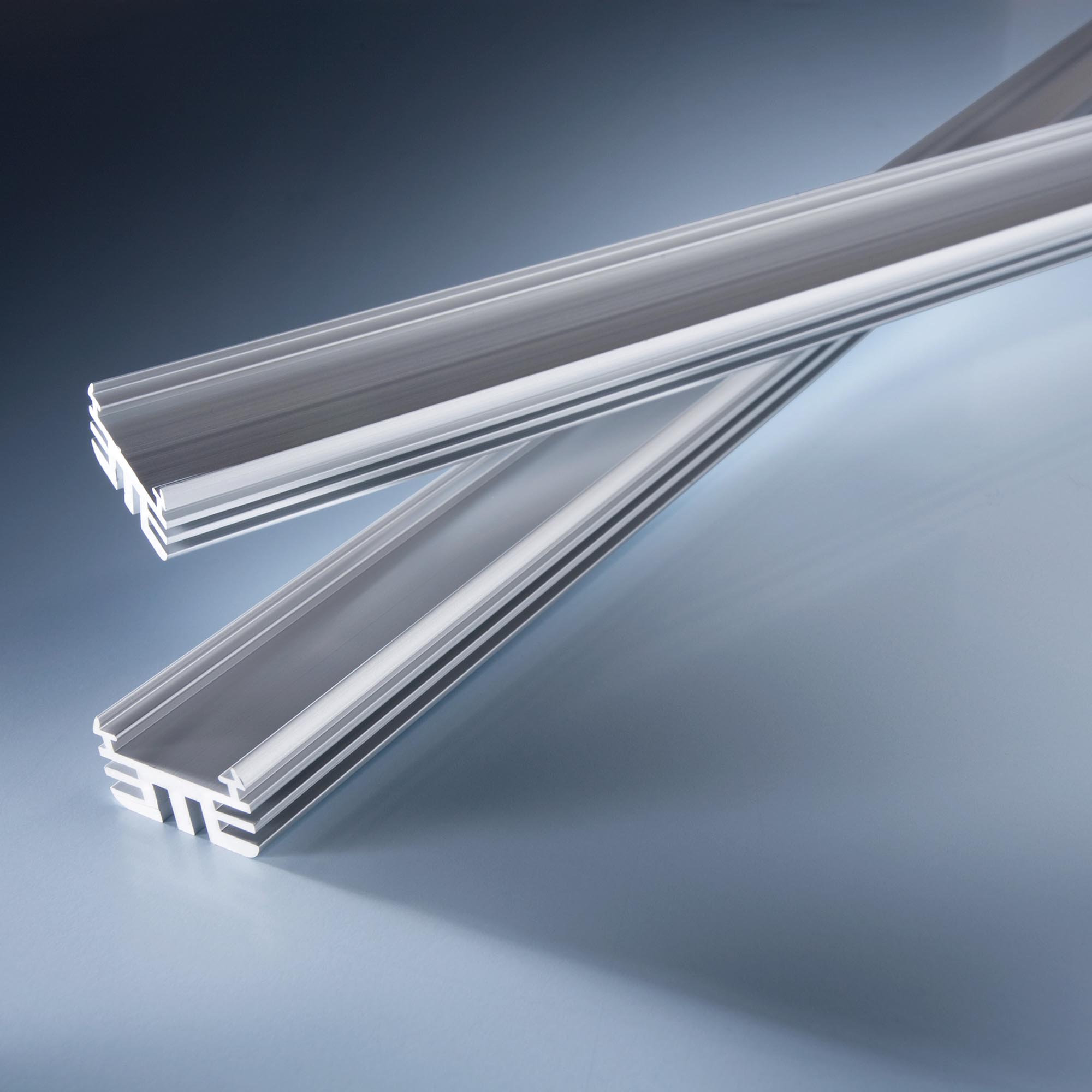

Build Your Own LumiBar-50 LED Strip Plug & Play LED Modules, Made in Germany, with Nichia 757 LED series, 500mm in length and 5mm to 20mm in width, with rigid PCB.

Step 1: Order Quantity (pcs)

How many modules do you need. While there is no MOQ, we recommend at least 50 meters. The ordered quantity will be delivered in strips of 50 cm, that you can then cut to the desired length, based on the cutting unit.

The cutting unit is based on the number of LEDs per meter and the choice of voltage, and can range from 3mm to 50mm (see image for details).

Step 2: LED Strip Width (mm).

The LumiBar-50 LED strip can be ordered in standard widths, from 5mm to 20mm. For different dimensions to those on offer, please contact us.

Step 3: LED Module PCB Material & Quality

The LumiBar-50 LED Strip will be made on FR4 PCB.

There are 3 quality levels:

- Economy PCB FR4: 1 PCB layer, 1mm PCB Material thickness, 1 oz PCB Copper thickness

- Best Value PCB FR4: 2 PCB layers, 1.6mm PCB Material thickness, 1 oz PCB Copper thickness

- Premium PCB FR4: 2 PCB layers, 1.6mm PCB Material thickness, 1.6 oz PCB Copper thickness

PCB has the following standard characteristics: White solder mask, black silk screen. HAL lead free surface finishing. Minimum trace spacing 0.2mm. Min hole size: 0.3mm (1.5mm aluminum). Minimum component spacing: 0.5mm. Minimum border spacing: 0.5mm

Step 4: LED Strip Forward Voltage (V)

To power a LED Strip and external power supply is required, that will ensure it receives the recommended current and voltage. Without it, the current in the LEDs will rise exponentially with the applied voltage, as a small change in voltage leads to a large change in current, until the maximum current is reached and the module burns up.

The external power supply can be a 12/24/48VDC constant voltage power supply.

You can choose the LED strip to be built with a current regulation mode so it can function with constant voltage transformers for 12VDC, 24VDC or 48VDC. For this purpose, the LEDs will be placed in series, with the current regulation component after each group:

- 12VDC (3 LEDs in series + current regulation component)

- 24VDC (7 LEDs in series + current regulation component)

- 48VDC (15 LEDs in series + current regulation component)

For any of the options above, the number of LEDs per Meter (at step 5) has to be divisible by the number of LEDs in series. For example, for 24VDC you can have 70 LEDs per meter but not with 60 LEDs. If you require 60 LEDs per meter, than the LED strip has to be at 12V or 48V.

For a project with large quantities of LED modules/strip connected in long rows, a constant voltage 24VDC circuit design is the best solution.

Step 5: How Many LEDs per strip:

The LED Quantity per Strip (pcs) determines the total luminous flux and application. Below some guidelines for Nichia 4000K CRI80 LEDs:

| Luminous flux /m | LEDs/50cm |

| <1000lm/m | 15-20 LEDs |

| 1000-3000lm/m | 35-49 LEDs |

| 3000-5000lm/m | 56-70 LEDs |

| >5000lm/m | 70-120 LEDs |

We recommend that the total number of LEDs that will be used to build your custom led strip to be as close as possible to a multiple of 5000.

Step 6: LED Color temperature

Different color temperatures create different visual effects and are appropriate for different environments. Color temperature is measured in Kelvin (K) on a scale from 'warm' to 'cool': The 'warmer' the light, the lower the number of Kelvin. The 'cooler' the light, the higher the number of Kelvin. You can read more about the recommended color temperature for a project in our blog.

Step 7: LED Type

The LumiBar-50 LED strip can be manufactured with the LEDs of your choice, including the latest generation Nichia 757 LED series, the industry leading 3030 Mid-power LEDs. The 757 LED series have industry's highest luminous efficacy (up to 222 lm/w) and reliability (up to 100.000h L70 lifetime). Each LED has a typical consumption of 0.2W at 65mA, for a luminous flux up to 45 lm.

Click here to see the current Nichia line-up.

Special Nichia 757 LED types include:

- Optisolis 757 & CRI99: LEDs with a spectrum close to natural light, CRI99, R9 minimum 85

- H6 757 Series & CRI90: LEDs that achieve a color quality better than traditional LEDs (Ra≥90, R9≥50, R15≥85) while maintaining an efficacy better than Ra≥80 LEDs.

- Vitasolis 757 Series & CRI80: Vitasolis LEDs emit a natural white color with a high content of blue-green energy proven to stimulate awakening and supports a vibrant life.

- HPS 757 Series & CRI70: LED that genuinely reproduces the emission color of High Pressure Sodium lamps (HPS), which is most often used for road lighting and outdoor lighting around the world.

- Rs060 Hortisolis Nichia: the Hortisolis™ Series of White LEDs from Nichia that are to be the most suitable LEDs for plant growth (found at 5000K color temperature selection).

- Special Color Redention: Light that brings out the best in the products such as meat (Rs020 found at 5000K) and fresh food (Rs030)

Not all color temperatures are available for every LED type or CRI.

Other options include Samsung, Seoul Semiconductor or Cree 2835 LEDs.

The LED strip datasheet will specify the Nichia/Samsung/Cree/Seoul Semiconductor LED part number.

Step 8: Current Regulation Mode

The Current Regulation component for the series of LEDs can be a simple resistor for Best Value Mode or a linear regulator for Premium Mode. The latter is recommended to achieve the maximum lifetime of the LEDs module.

Step 11: Electrical Connection Type

- Solder Pads: the LED module will have 2 pairs of Solder Pads at each end, for + / - connection. For LED modules with cutting unit, the 2 pairs will be present at each end of the cutting unit.

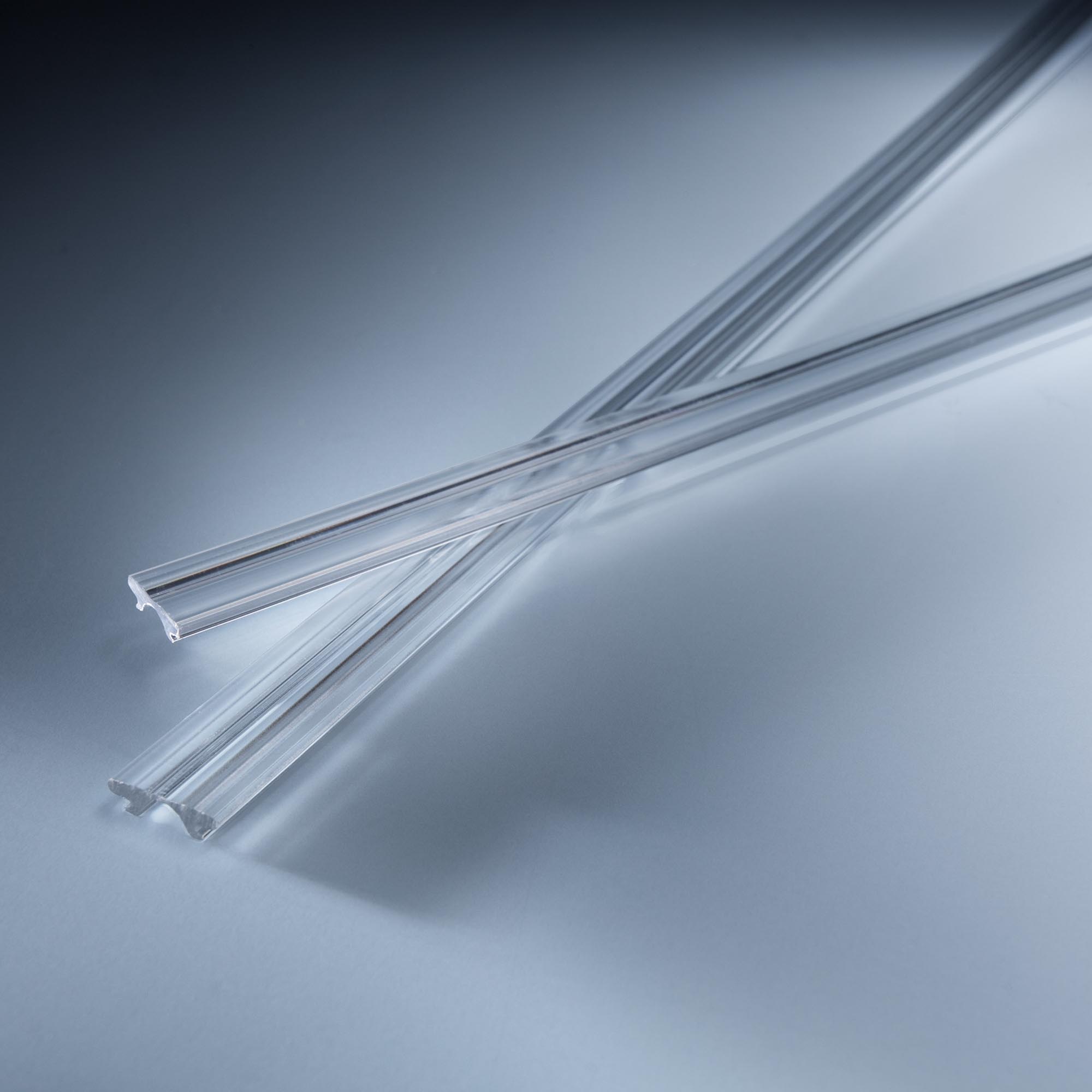

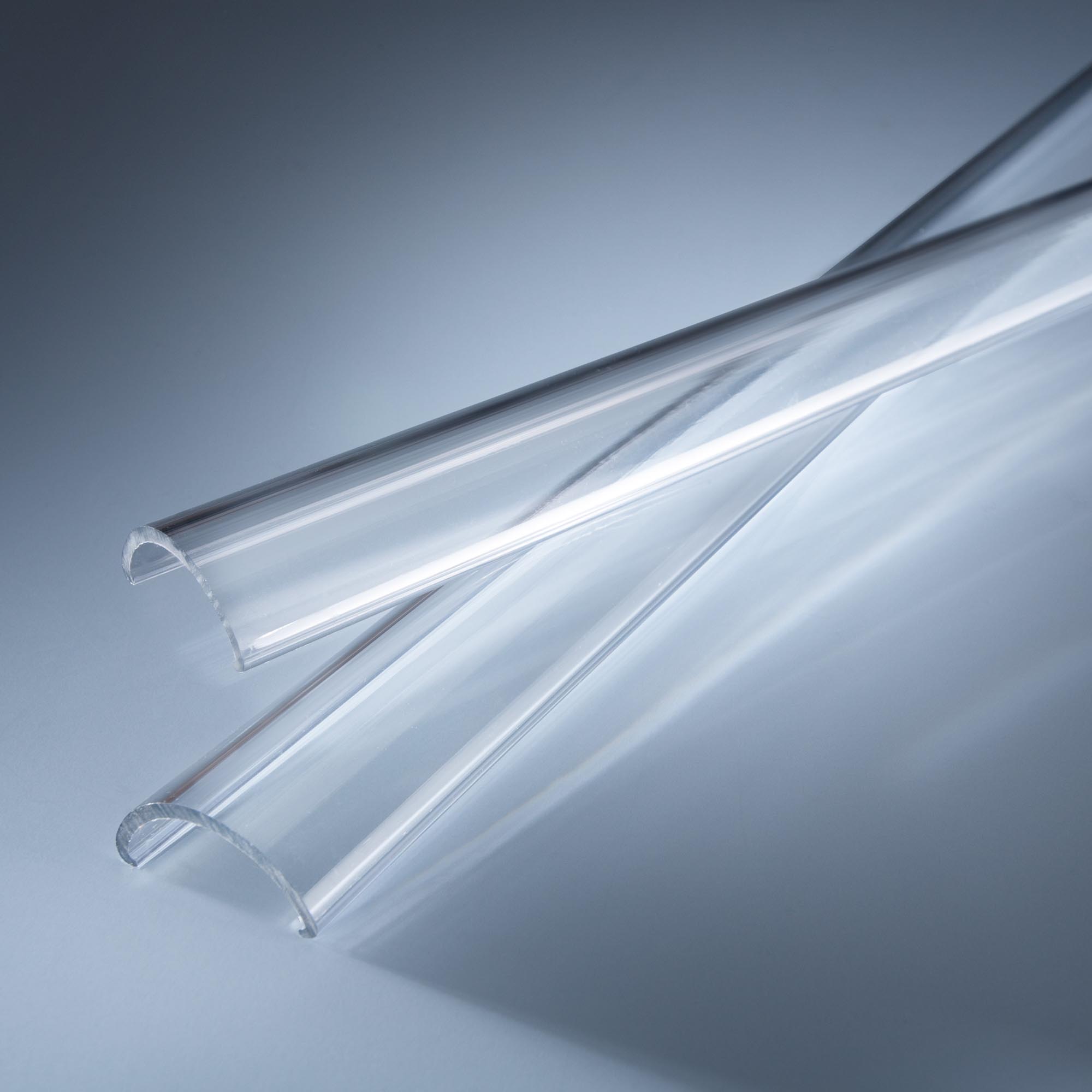

- Surface Connection: the LED module will have 2 pairs of Plug-in connectors at each end, for + / - connection. For LED modules with cutting unit, the other connections points will be solder pads. There are four types of surface connectors available, each being able to accommodate a different range of wire diameters (AWG). AWG is the US standard measure for the diameter of electrical conductors. The Plug-in connectors allow the cable to be connected without using a soldering iron.

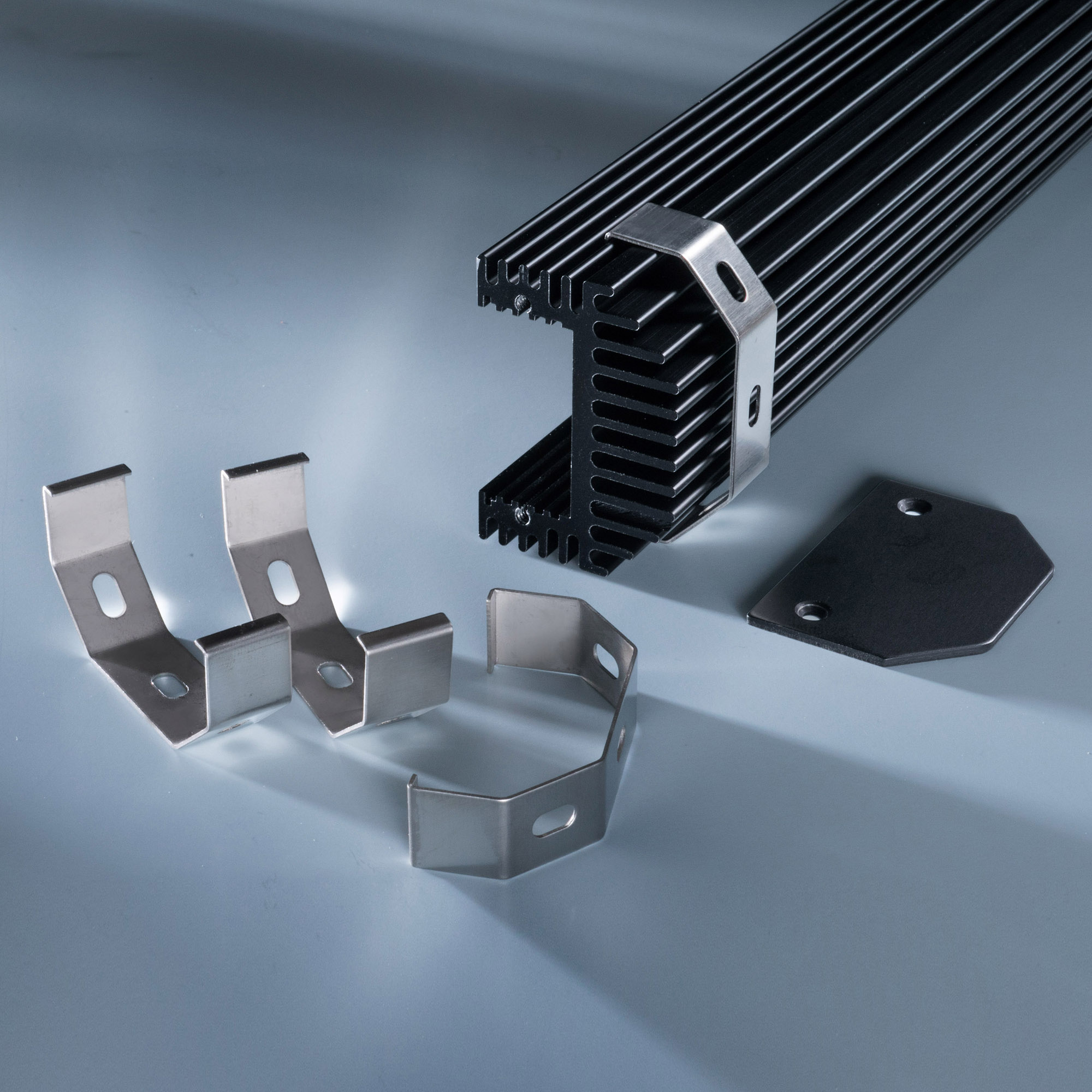

- Multibar PCB Connection: The LED module will have connection pads compatible with our MultiBar Plug & Play connection system that makes it easy to connect the LED modules into long light strips without the need for soldering. Many types of MultiBar connectors are available. You can order the most popular types with the custom LED module at a special price (Multibar Connector Type), or later at our standard price. For LED modules with cutting unit, the MultiBar connection system will also function with each cutting unit.

- Wire connection: The LED module can be built with a +/- wire at one or both ends, with your specified length. We recommend 500mm maximum as to avoid voltage drop.

Step 13: Scope of Delivery

The order process and online payment can be made for the full Order Quantity (meters) or for drawing, design or samples. Based on your choice, the scope of delivery and the payment will be:

- Order Quantity (pcs): the full quantity entered at step 1, including drawing, design and samples.

- Design and Samples Only: Drawing, Design and 5 samples of maximum 50 cm each, for the LED strip with the specifications from the order.

- Drawing Only: The drawing of the LED strips, including:

- Dimensional drawing, with position of the LEDs, solder pads, current regulation components, printed information on the PCB.

- Summary of the main characteristics (technical data of the cutting unit), including: dimensions, operation mode, voltage, current, power, color temperature, luminous flux, efficiency, CRI, LED type.

- PCB information: base material, layers, copper.

Step 14: Advanced Options

If you have the design of your LED module already made in detail or have special requirements, then we recommend filling the relevant details in the ADVANCED OPTIONS section. Only fill in the fields relevant for you. You can also provide this information via email, in the Design validation stage.

- Your part number: We can print your own part number that you fill, on the PCB of the LED strip, maximum length 10 characters. It will be printed in addition to the information required by European Union law: manufacturer, manufacturer part number, relevant technical information (such as: voltage, current, color temperature, luminous flux, TC), CE, ROSH, Recycling logo.

- Desired Power Consumption per Meter (W/m): the power consumption per meter for the LED strip will be considered during the design process. We will inform you if this value is too low or too high because of other technical factors.

- LED Module max. Row Length (m): Many projects require multiple LED modules/strips to be powered together in a line. This information can help to properly design the PCB of the LED module.

The advanced options should not change the characteristics of the LED module and/or the order value.

OPTIONAL: Upload Files (after order is made):

Upload files: If you have specific design requirements for the custom LED module or strip, that does not change the characteristics of the LED module, you may upload them from the upload section or from the page at this link. Accepted files are PDF, Gerber, PCB file. We accept Zip, Rar format, maximum 10MB for all files. Only upload these files after you complete your order! Your order number and email address are required.

| SKU | byo_n5000 |

|---|---|

| Luminous Flux per meter | 10000 |

| Dimmable | Dimmable |

| Strip Type | Rigid |

| Dimensions: Length (cm) | 50 |

| Brand | Lumistrips |

Custom LED Module Order Terms & Conditions

When your order is confirmed, we will manufacture the custom LED strip or module at our factory in Germany, based on the specifications you provided. Payment is required for order confirmation. Orders with successful online payments are considered confirmed.

Here’s how the timeline looks once we confirm your order:

- Design validation: we will check your order details and additionally supplied information (uploaded file), within 5 working days.

- Design Draft: You'll see the first drawing of your custom LED strip or module within 2 weeks.

- Datasheet: After the drawing gets your approval, we'll create for you the custom LED strip datasheet, within 2–4 weeks.

- Samples: You may request to receive samples, when you order or receive the datasheet. This option has an extra cost and adds to the total delivery time of your order. Details will be provided at the time we receive your request.

- Mass Production: Once you approve the datasheet and/or samples, we'll start the full production, which will take 6–10 weeks.

With us, your investment in custom LED technology is transparent, with clear steps and predictable timelines.

Custom order changes, cancelation, refunds, returns:

1. Changes to the specifications of the module can be made during the Design Draft process. These changes can be caused by incorrect data supplied to the online order system, such as technical specifications that are impossible to produce or wrong data.

For LED modules with custom dimensions, the decimal separator is the dot (.)

Changes that lead to additional costs will result in the recalculation of the order value.

2. The custom LED module order can be canceled:

- Within 5 working days for a 5% cancelation fee

- After receiving the design draft for a 15% cancelation fee

- After receiving the datasheet for a 25% cancelation fee

- After receiving the samples for a 25% cancelation fee + samples cost.

Once the datasheet and/or samples are approved, and mass production is initiated, the order cannot be canceled. Custom-made LED products cannot be returned. We reserve the right to cancel orders at any time, up to the point of delivery. Orders canceled by our decision will be refunded in full. We will not be responsible for any costs or associated damages caused by order cancelation or delays in delivery.

Custom LED Module warranty:

We provide a 5-year warranty for all custom LED modules, based on our standard warranty terms.

The operating temperature is a crucial facture in LED module lifetime. The maximum operation temperature (TC) will be specified in the design stage and written on the product and datasheet. It is important that you use thermal management to prevent exceeding of the maximum value. If it is not possible, you have to inform us during the design stage.

Shipping Methods and Cost:

We also accept shipping via your express account with DHL, TNT, UPS or FedEx. After we receive your order please contact us via email with this choice.

For bulky parcels with custom LED products and accessories, the standard shipping costs added via the online order process might not fully cover the safe and timely delivery of your order. If we discover, before shipping your order, that the shipping cost is greater than already paid or what we can cover for free shipping, we may ask you to cover the extra cost. In case of orders the orders free shipping, the maximum ship cost covered by us is 40€.

Custom LED Module certifications:

Built in Germany, the custom LED modules have the following certifications:

- CE

- ROSH

- REACH

On demand, other certifications ca be provided (for a price):

- UL

- CSA