COB LED Lighting: Efficiency, Power, and Precision for Every Application

- By Ledrise Led Professional

- Oct 20, 2025

Lines of light are a new trend for interior lighting, especially because of the possibility to build a personalized installation. The iluminated lines can be place on walls or ceiling, in the form of recessed, surface or suspended lighting fixtures.

These lighting fixtures are made with an LED strip inside an aluminum profile that has a translucent white cover, can be many meters long, installed in patters or geometric shapes.

Compared with indirect cove lighting, also a popular trend in lighting design, lines of light are more energy efficient but can have greatly increased glare. For this reason direct lighting with lines of light should be designed with care and almost always be dimmable.

Let's see how we can achieve the best results with lines of light.

For residential applications, LED lights with a CRI of at least 90 are recommended for bedrooms, living rooms, bathrooms, and kitchens. For business applications, lights with a CRI of 80 are suitable for general work in offices, while lights with a CRI of 97 are recommended for offices where work with colors is involved, as well as design studios and photography studios. For commercial applications, LED lights with a CRI of 90 or higher are recommended for electronics stores, hardware stores, and jewelry stores, while lights with a CRI of 98 are ideal for interior design stores.

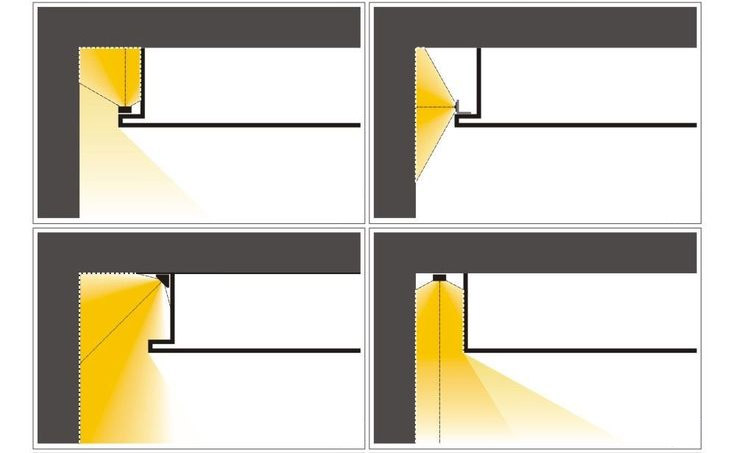

Cove lighting with LED strips has become increasingly popular in recent years as it offers a subtle and sophisticated lighting approach that can transform the mood and ambiance of a space. By utilizing LED strips hidden within a cove in the wall or ceiling, a seamless line of light can be created that illuminates surrounding surfaces and reflects into the room, creating a soft and gentle glow similar to natural light from a hidden window. In this blog post, we will explore the benefits and techniques of using LED cove lights in lighting design.

Advantages of LED Cove Lighting

LED cove lights are a versatile and energy-efficient lighting solution suitable for a wide range of interior spaces, including living rooms, bedrooms, kitchens, lobbies, restaurants, and retail spaces. The flexibility in design is one of the significant benefits of LED cove lights, as they can be installed in various shapes, sizes, and colors. This allows for endless possibilities in creating unique and captivating lighting designs that can be customized to meet individual preferences. LED cove lights also come with dimming capabilities, which allow for greater control over the intensity and mood of the light.

Another significant advantage of LED cove lights is their energy efficiency. Compared to traditional lighting sources such as incandescent or fluorescent bulbs, LED lights consume less energy and have a longer lifespan. This not only reduces energy costs but also lowers the environmental impact of the lighting system.

Factors to Consider for Cove Lighting Installation

Several factors need to be considered when installing LED cove lights, such as the location of the cove, the type of LED strips to use, and the color temperature of the light. Working with a professional lighting designer or electrician can ensure that the installation is done correctly and efficiently

Careful design of the lighting for your home will ensure that the right amount of light is where and when needed, switched on conveniently. Lighting should avoid over-lit areas, and give control and flexibility to create lighting effects for different situations. Well-designed lighting will be inherently easier to use and will function in an energy-efficient way.

The best approach to home lighting design is to use three levels of lighting: general lighting, task lighting and accent lighting. By combining these three levels, the recommended lighting level for each room or activity should be obtained, as below:

| Recommended lighting levels for the Home | in Lux |

| Living rooms general | 50-150 |

| Casual reading | 150 |

| Study | 150-750 |

| Bedroom general | 50-150 |

| Kitchen general | 150 |

| Kitchen working areas | 400 |

| Bathrooms | 150-300 |

| Halls and landings | 100-150 |

| Stairs | 100-150 |

| Dining rooms | 150-450 |

The three levels of lighting

1. General lighting should ensure a sufficient minimum level of light in the room. There are plenty of LED light sources that can be used for this purpose: LED modules, strips, luminaries or spotlight. Decide on the desired illuminance level (lux). In living rooms and bedrooms in particular, give a certain degree of flexibility (through control settings/dimmers) so that occupants can raise or lower the general lighting around the set level. Design for the upper end of the Lux ranges in homes with elderly occupants, which generally appreciate a higher level of general lighting. A minimum level of general lighting is required for safe movement in the home, especially on the stairs, but sufficient general LED lighting is considered important for general well-being.

2. Workplace lighting is needed for certain activities at home, such as reading, preparing food and working from home. LED lamps must be carefully selected, correctly positioned and controlled. Recommended are LED spot lights and high flux LED modules. Lamps or sockets are needed in the right places to ensure flexibility in the availability of work and accent lighting. Depending on the task, LED workplace lighting may be required at different levels. The color rendering of the light is also very important for some activities, we recommend LED lights with CRI 97 or more.

3. Accent lighting contributes to the ambiance of a house and is usually done with LED spots and strips. As with workplace lighting, LED luminaires (or sockets) are placed in the right places to emphasize architectural features, furniture and ornaments. Accent lighting is a more personal matter, and depending on the circumstances, spotlighting or floodlighting can be useful.

For each of these levels of lighting, controls can provide a range of lighting options. So in an living room there could be separate controlled circuits for:

Similar control patterns can be considered in other rooms, with dimmers providing a different lighting atmosphere in salons, dining rooms and bedrooms. Advanced controls, sometimes controlled by a mobile phone or a tablet app, that allow remote adjustment of the amount of light and its color are increasingly popular. Lighting is establishing itself as a lifestyle statement, and houses with new and innovative lighting systems are perceived as a marketing advantage.

LumProtect represents a groundbreaking advancement in LED lighting technology, offering an innovative lamination process that enhances the durability and flexibility of LED modules. This cutting-edge technology applies multiple polymer layers onto electronic assemblies, combining heat and high pressure to create a product that withstands environmental challenges without sacrificing flexibility. Key features include enhanced durability against environmental factors like humidity and UV rays, high transparency with minimal color shifts, and significant mechanical strength. The versatility of LumProtect extends to various applications, from outdoor flexible lighting solutions to aesthetically pleasing LED wallpapers for indoor spaces, demonstrating its adaptability in both residential and commercial settings.

The technology behind LumProtect involves a meticulous lamination process that maintains the flexibility of LED modules while increasing their resistance to physical and environmental stress. With technical specifications focusing on mechanical and optical parameters, LumProtect meets the highest standards of durability and visual quality. This article delves deep into the nuances of LumProtect, exploring its myriad applications, sustainability aspects, and the potential it holds for revolutionizing lighting design. For a comprehensive understanding of how LumProtect is setting new benchmarks in the world of lighting, we invite you to read the full article and discover the future of lighting technology.

In this blog post, we celebrate the 30th anniversary of the high brightness blue LED, a pivotal innovation in lighting technology by Nichia Corporation. This remarkable journey began with a modest announcement in November 1993 by Nichia, a then-obscure chemical company based in rural Tokushima, Japan. Eschewing grandiose launch events, Nichia chose a simple interview with a local newspaper to introduce their groundbreaking blue LED, the NLPB500. The post explores the early applications of blue LEDs in traffic signals, displays, and scanners, and the subsequent development of the 3-in-1 LED for high-resolution indoor displays.

This led to the revolutionary creation of white LEDs, combining blue LED technology with YAG phosphor. The impact of this innovation extends far beyond lighting, influencing industries and contributing to environmental conservation. The post also discusses the future prospects of LED technology, including ongoing research in areas like Li-Fi and the potential of emerging technologies like OLEDs and quantum dots. To learn more about this fascinating journey of innovation and its far-reaching implications, we invite you to read the full article and join us in celebrating this significant milestone.

Navigating through the intricate world of LED lighting, this article provides a comprehensive guide on LED dimming, delving into varied dimming methods and exploring their applications and advantages. It emphasizes the role of transformers and the importance of compatible dimming options, shedding light on how LED technology interacts with different dimming technologies, including wireless dimming solutions like Bluetooth and Zigbee, and wired systems like DALI and KNX.

The article is a reservoir of knowledge, ideal for those keen to understand the nuances of dimming LED lights and how modern technology has enhanced the way we control light. Whether you’re a homeowner looking to revamp your lighting system or a professional seeking detailed insights, this article offers valuable information. Dive into the full article to illuminate your understanding of LED dimming solutions and to explore which technology aligns best with your needs.

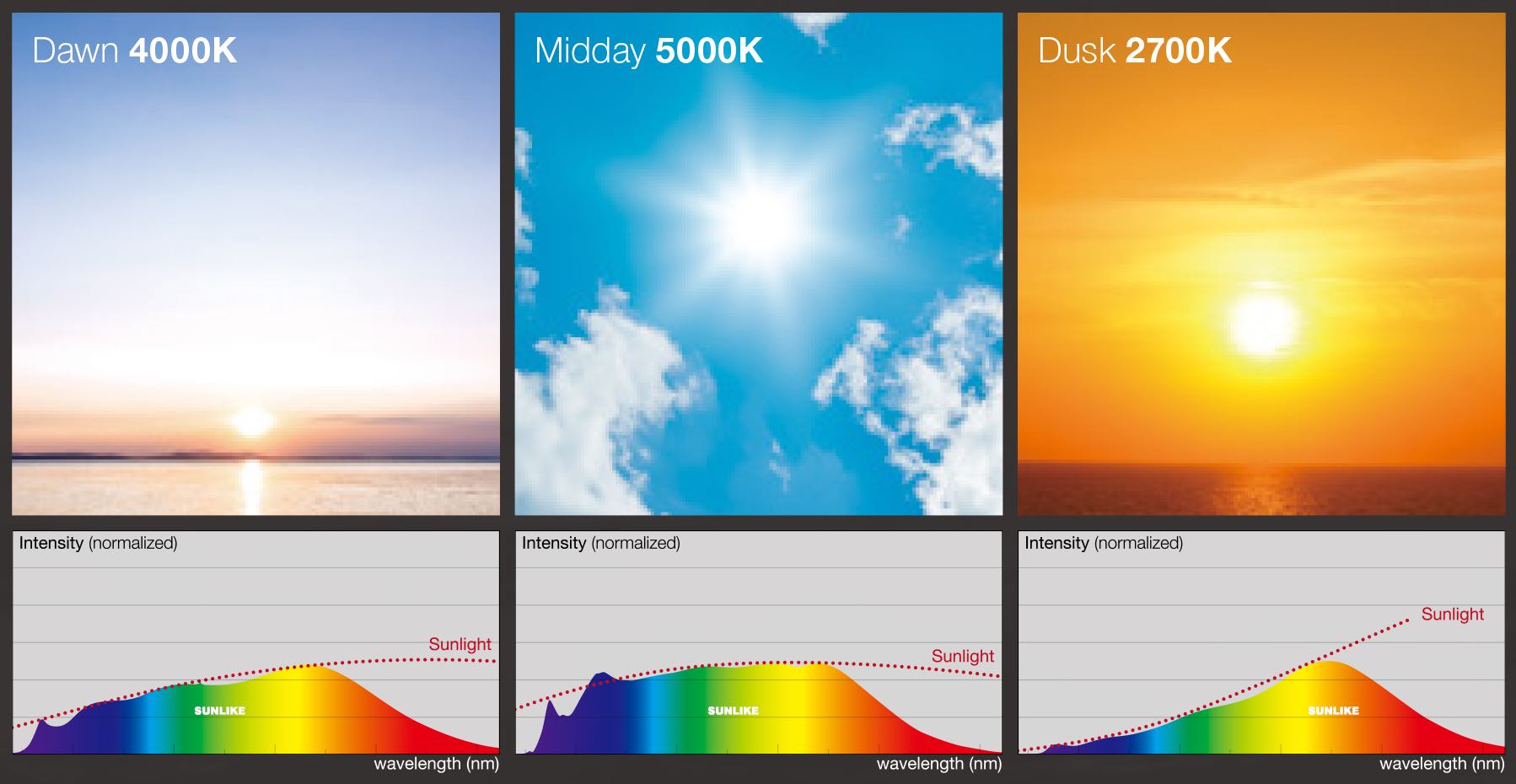

Casambi, a pioneer in Bluetooth Low Energy (BLE) wireless lighting control, has teamed up with LED technology specialist Seoul Semiconductor to offer lighting designers precise control of LED strips, modules and luminaires that use the new SunLike technology that matches the spectrum of sunlight. For the first time, this development puts true human-centered lighting in the hands of designers.

Users can use Casambi's Bluetooth-based wireless control system and app with products that include SunLike series LEDs to precisely adjust the light level, knowing that the spectrum reflects real sunlight, a key ingredient for Human-centric lighting

Human-centric lighting describes lighting designed to work with the natural rhythms of the human body. It is based on the well-known fact that the human eye recognizes the presence of a certain wavelength of blue light in the spectrum of sunlight and derives the time of day from this. In this way, light helps to regulate our sleep-wake cycles and other physical rhythms and has a significant impact on our mood and well-being.

Human-centered lighting takes advantage of this effect by adjusting its brightness and color temperature during the day to mimic natural light.

Casambi allows control of the lights through a timer or a variety of presence/movement sensors and daylight sensors. It can control lights that change colour temperature over a very wide range, and designers have the freedom to configure dimming and create scenes or animations for the application.

Casambi allows control of the lights through a timer or a variety of presence/movement sensors and daylight sensors. It can control lights that change colour temperature over a very wide range, and designers have the freedom to configure dimming and create scenes or animations for the application.

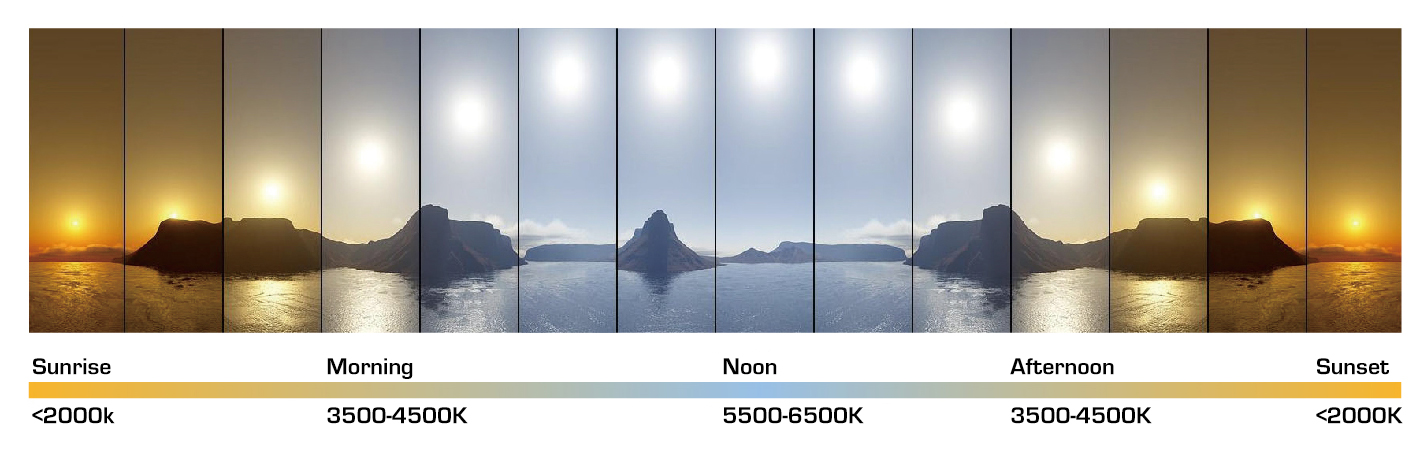

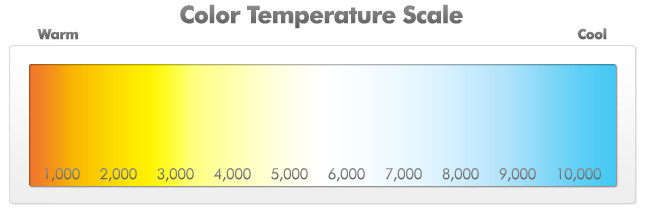

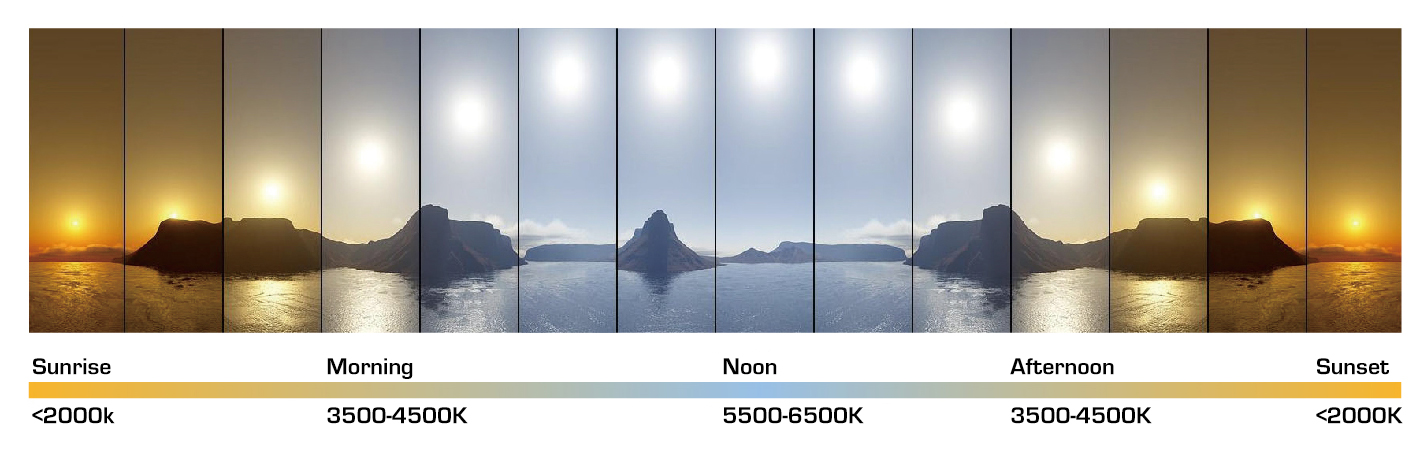

Natural light is a beautiful and dynamic source of white light, with its tone and brightness changing throughout the day and the seasons. The tone of white light is called color temperature, which is measured in degrees Kelvin (K). The color temperature of natural light changes during the day, from a warm orange-red hue of about 2000K at sunrise and sunset to a cooler blue-white hue of about 5500-6500K at noon. In the shade, the color temperature can even reach up to 8000-10000K, which is an extremely cool blue-white hue.

Artificial light sources are available with all relevant color temperatures of sunlight. Some traditional light sources, such as incandescent lamps, can only be manufactured with a fixed color temperature of 2700K. However, with the advancements in LED lighting technology, we now have access to LED light sources that can be produced with a wide range of color temperatures, from 2000K to 10000K, with the most common color temperatures falling within the 2700K to 6500K range.

One of the key benefits of LED lighting is the ability to produce light at a specific color temperature, which can help create the desired mood or atmosphere in a space. LED lights with warm color temperatures, such as 2700K, can provide a cozy and relaxing atmosphere, making them great for use in living rooms, bedrooms, and other spaces where a sense of comfort is desired. Cooler white LED lights, with color temperatures in the 5000K to 6500K range, can help create a more energizing and focused atmosphere, making them ideal for use in offices, factories, and other workspaces.

An important factor to consider when selecting LED lighting color temperatures is the psychological and physiological effects of light on people. The color temperature of light can affect mood, energy levels, and even sleep patterns. Warm white light with a color temperature of 2700K to 3000K can have a calming effect on the body, making it a great option for spaces where relaxation is a priority, such as bedrooms or living rooms. Cooler white light with a color temperature of 5000K to 6500K can have an energizing effect, making it ideal for workspaces, such as offices or factories.