- Home

- Ready-Made LED Strips & Modules

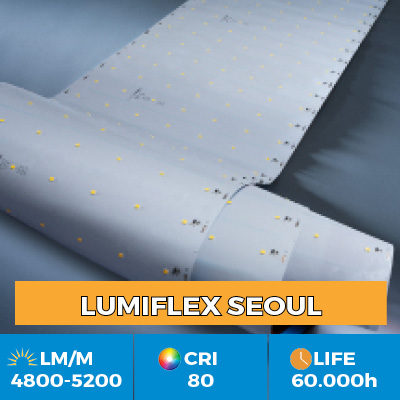

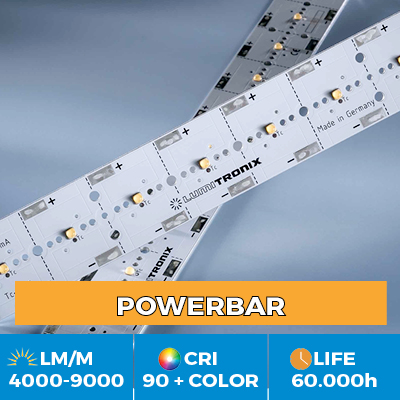

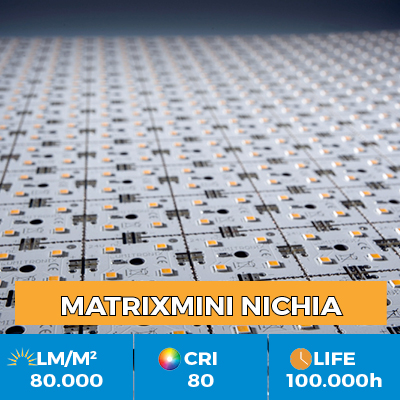

- Our Professional Backlight LED Modules

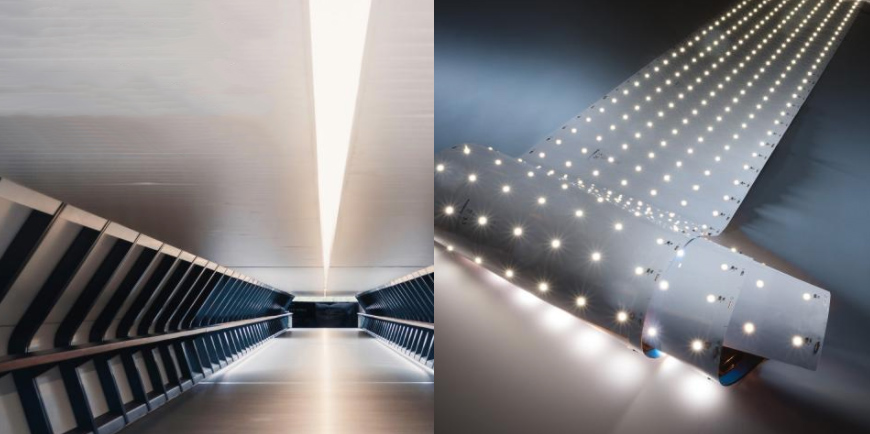

Our Professional Backlight LED Modules

Professional LED modules with Nichia, Samsung or Toshiba LEDs

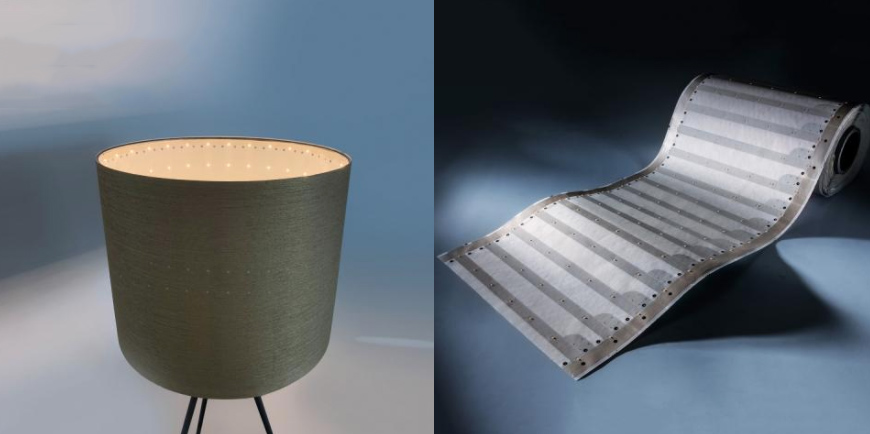

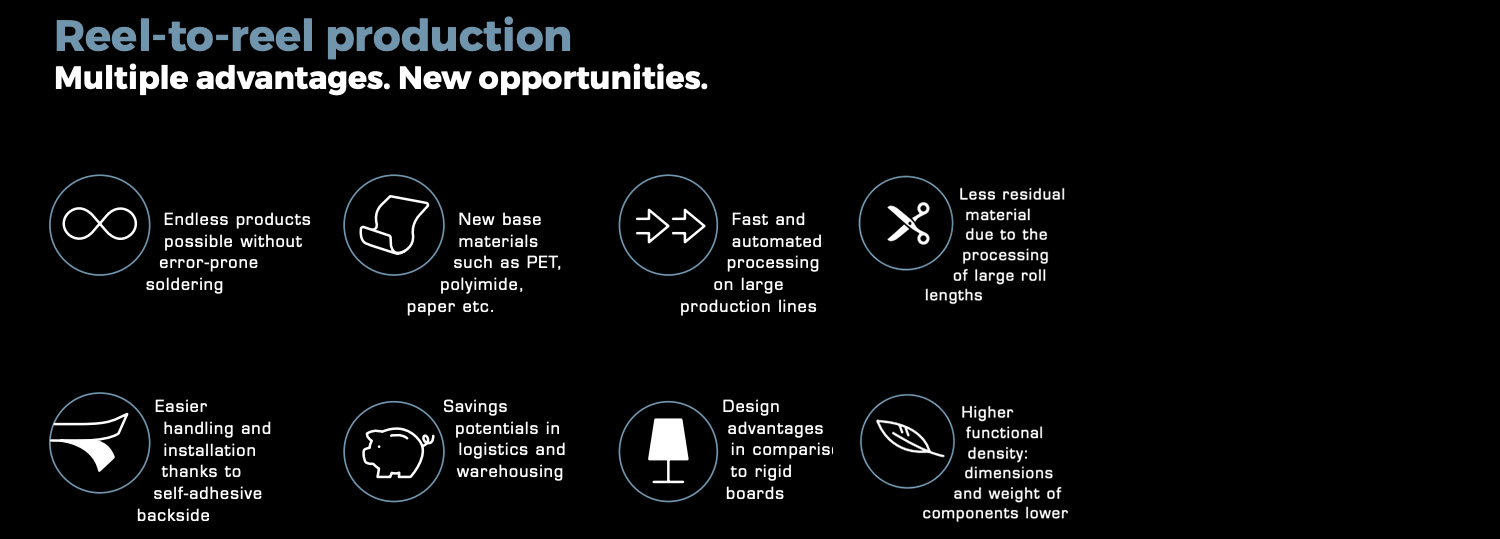

Our new Flex production line in Germany will expand your possibilities, with new materials used in reel-to-reel manufacturing

In our new production line in Germany we deployed the innovative manufacturing technology of plasma direct metallization, to turn flexible substrates into electrical conductive and solderable circuit boards, even those that before have not been suitable for an assembly with electronic components.

With this patented process, the new materials we use as base for our LED strips and modules will open up many new application possibilities in the lighting industry and beyond.

A new such material is the solderable flexible paper as used in the Paper-Flex, a cost effective PCB that is open to diffusion and therefore ideal for large-area applications such as wallpaper or advertising spaces.

Paper-Flex is a reel of luminous, flexible paper, with an amazing lenght of 24.85 m and surface area of 8.69 square meters, that will light up at once from a 24VDC transformer. Many new applications are possible: from luminaire production, to furniture, packaging and advertising industry.

Using solderable flexible PET is another innovation, as in the case of the extremly bright Z-Flex980 LED strip. The PET is a plastic cheaper than polyimide, with very good strength, high resilience and low weight.

The Z-Flex980 LED sheet can bring intense light to wide surfaces with its wallpaper like design, with fast and easy installation. Very luminous lighting fixtures with unique designs or shapes can be created. One reel of Z-Flex980 is 5.6m long and powered at 24VDC will light up at once.

PET is also used as PCB in the Z-Flex540, a 20 mm wide LED strip for building extremely bright linear fixtures with minimum assembly work due to the Zhang-compatible dimensions and plug and play design, with connectors. The Z-Flex540 is available in reel format, 5.6m long with 20 modules and can be cut at every 28 cm, which is the shortest possible length. Each module functions at a low voltage of 8.25V and respects the SELV standard.

Our new reel-to-reel production line offers many advantages, from delivering customs designs without the error of soldering to the use of new base materials that make new designs possible, with easier handling, installation and transportation.

Our Professional LED Modules Quality difference

Our professional LED modules use LEDs from market leaders and are made in Germany.

We develop and produce our LED modules at a state of the art facility in Germany, with the highest quality standards and by using only LEDs from market leaders such as Nichia, Samsung or Toshiba.

- Nichia is the LED market leader, with over 25% market share and decades of experience. Nichia researchers invented the blue and white LED production technology, also receiving the Nobel Prize for this achievement. Nichia LEDs are the most efficient (200 lm / w efficacy), durable (> 100,000 hours) and are also available with unique technologies such as Optisolis, CRI98+ natural light spectrum and Rsp0a, special white light for horticulture.

- Samsung is in the top 10 of global LED manufacturers and a well-known brand, renowned for the high performance of its products combined with the competitive price

- Toshiba is a Japanese conglomerate with a history of more than a century, now specialized in semiconductors, electronics and hardware, with nearly 20,000 employees and an annual turnover of 40 billion USD. Toshiba has built the TRI-R technology and built the LED chips used in SunLike CRI97+ LEDs produced by Seoul Semiconductor in South Korea. With the new SunLike™ TRI-R™ technology from Toshiba-SSC (Seoul Semiconductor) and our strips and modules you can always enjoy a natural light source with the light spectrum very close to the sun.

We are a specialist in high performance LED strips and modules. As part of the early success of LEDs we have extensive application knowledge from a wide range of sectors. Since 2010, we have developed and produced our LED strips in a state-of-the-art production facility in Germany. Our strips have been used successfully in a wide range of application and developed specifically to meet customer specifications in Europe, Asia or America.

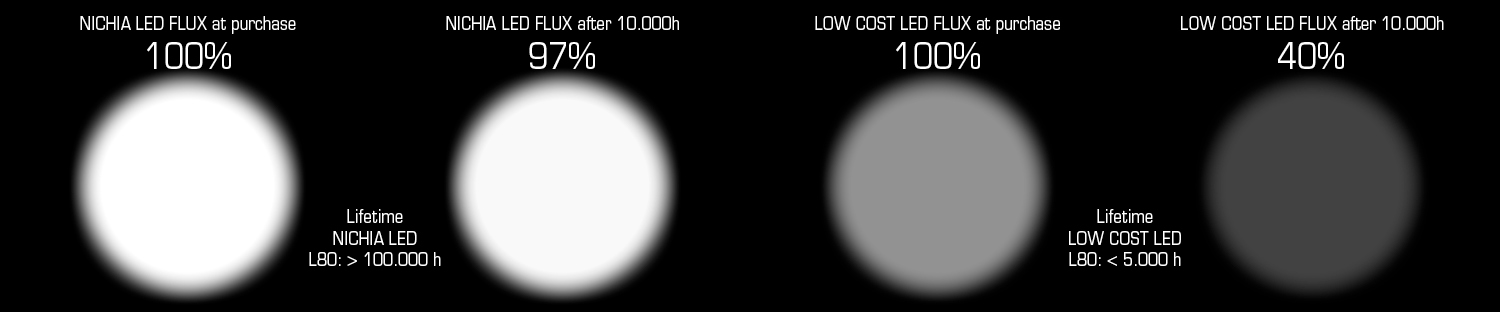

The difference between the quality and performance of our professional LED modules and low budget LEDs module is evident from the first power on, and in time the gap increases even more.

Our strips and modules:

- Use LEDs from top brands

- Perfectly match in real world applications the performance values in their datasheet

- Have 100.000 hours lifetime*

- Function perfectly at high temperatures that would destroy many other LEDs

- The LEDs used have 10.000 hours lifetime L80, TM21 tests**

- Come with a 7 years warranty***

- Have the best luminous efficacy, including at high temperature

- Can have a luminous flux up to 8000lm or the heighst CRI on the market CRI98+

- Use professional grade PCB for best resistance, current flow and heat transfer

* for Nichia LED modules only ** for Nichia and Samsung LED modules *** for Nichia LED modules and registered projects

1) Nichia LEDs have the best lumen maintenance on the market

Most professional LED modules on our offer use Nichia 757G LEDs.

After 10,000 hours of operation, a Nichia 757G LED has the best lumen maintenance, keeping 97% of the first light at high operating temperatures. The Unrivaled durability comes from the unique package design and high quality of the used materials, Nichia being also the manufacturer of the chemicals in the LED component.

In fact, a Nichia LED modules will run in most cases for over 100,000 hours, after which it will lose only 20% of its luminous flux. 100,000 is a very long period, at least 10 years of operation without stopping in a shopping center or decades of daily use in the place.

To keep the cost low, a low budget LED uses a weak design and low quality materials, resulting in 60% loss of initial power in less than 10,000 hours. In just 1000-3000 hours, that can pass in months, a strip with such LED is too dim for its original purpose and has to be replaced.

Luminous flux stability for the Nichia 757G LEDs is supported by 10,000-hour tests, according to the LM-80 standard. Lifetime (light at 80%) is calculated according to TM-21, both of which are internationally recognized standards and used by all major manufacturers.

2) 3 Macadam Elipse sorting for uniform white light, LEDs in a batch of the same shade of white that it keeps in time

On our professional modules, all LEDs have the same color temperature as all LED modules in a delivery. Uniformity is also maintained on a future order. The reason is that we use only LEDs with the 3 Macadam Elipse sorting standard.

The phenomenon of shifting white color temperature after many hours of operation is not visible for our professional LED strips (for example, those with the Nichia 757G) because we use only the best of LEDs, like Nichia 757G.

In contrast, for cheap LEDs, a post-production LED sorting standard is not used as it increases the price. Thus, on a module from one to another we can see many shades and light intensities. The requirement that the next order has similar color temperature is impossible to accomplish. Moreover, after just a few thousand hours, each inexpensive LED changes its hue and looses brightness independent of what happens to others on the module.

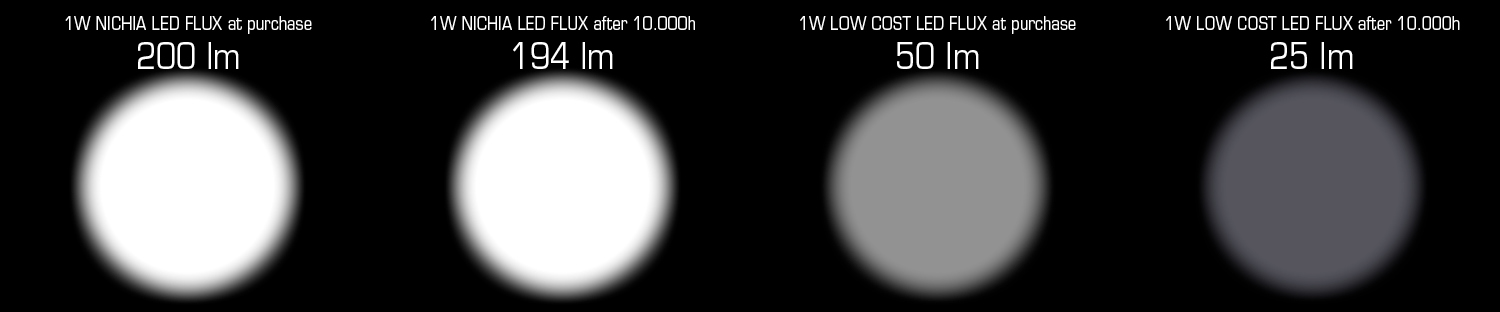

3) The highest luminous flux with the lowest energy bills: LEDs are up to 5 times more energy efficient

Depending on the technology used, LEDs may have a different light output for the same power consumption. The difference in light efficacy (lumens per watt) from one LED to another may be 500% and has a very high influence on the production price.

The Nichia 757G LEDs used in most of our professional strips have the highest light efficacy on the market, of more than 200 lumens per watt compared to an inexpensive LED that has around 50 lumens per watt.

4) Natural Colors: LEDs have the best light quality, with a spectrum similar to daylight

The purpose of a light source is to reproduce the natural light, with direct connection with the way our eyes perceive colors. The CRI index is the best known method to express the attribute of the light source to be of the same quality as the sunlight, in which case the CRI value will be 100.

In a light source with CRI of less than 80, colors are no longer perceived correctly, a phenomenon that is pronounced at CRI 70 or less. For example, a pure red material seen in the daylight can seem as a red-brown in the light of an LED with CRI 65.

In addition, LEDs with a CRI of less than 70 can be tiring for the eyes, causing headaches or even mild dizziness.

All professional LED modules in our offer have a CRI of at least 80, with up to 98 available on request.

The low budget LEDs on the market have CRI of 70 or less and their light greatly distorts color shades, especially warm colors such a red, orange or brown.

Our Professional LED modules have a high-quality light, CRI 80-98+ for the best color perception

A cheap LED module has poor light quality, CRI <70 that makes colors look different