In the modern workplace, lighting transcends its basic function of visibility; it plays a pivotal role in influencing employee well-being, productivity, and overall satisfaction. As organizations strive to create environments that foster efficiency and comfort, understanding the nuances of office lighting becomes essential.

The Science of Light in the Workplace

Light impacts our circadian rhythms, mood, and cognitive functions. Inadequate or improper lighting can lead to eye strain, fatigue, and decreased concentration, while well-designed lighting can enhance alertness and performance. According to the Illuminating Engineering Society (IES), appropriate lighting levels vary depending on the task and environment, emphasizing the need for tailored lighting solutions

Recommended Illuminance Levels

Illuminance, measured in lux, quantifies the amount of light falling on a surface. The IES provides the following guidelines for office environments:

- General Office Work: 300–500 lux

- Detailed Tasks (e.g., drafting, technical drawing): 750–1,000 lux

- Conference Rooms: 300–500 lux, with adjustable lighting for presentations

- Reception Areas: 200–300 lux

- Corridors and Stairwells: 100–200 lux

- Storage Rooms: 100–200 lux

Linear light fixtures are the recommended way to light up working spaces. The recommended light levels for different types of work spaces and the corresponding luminous flux of the linear fixture are detailed below:

| Activity |

Illuminance

(lx, lumen/m2) |

Linear Light in lumens per meter |

| Areas with traffic and corridors - stairways, escalators - lifts - storage spaces |

100 |

2000 |

| Working areas where visual tasks are only occasionally performed |

150 |

2000 |

| Warehouses, archives, loading bays |

150 |

2000 |

| Coffee break room, technical facilities, ball-mill areas, pulp plants, waiting rooms |

200 |

2000 |

| Easy office work |

250 |

2000 |

| Normal office work, PC work, show rooms, laboratories, check-out areas, kitchens, auditoriums |

500 |

4000

|

| Mechanical workshops, office landscapes |

750 |

6000 |

| Normal drawing work, detailed mechanical workshops, operation theaters |

1000 |

10000 |

| Detailed drawing work, very detailed mechanical works, electronic workshops, testing and adjustments |

1500 |

10000 |

| Performance of visual tasks of low contrast and minimal size for prolonged periods of time |

2000 |

10000 |

| Performance of very prolonged and exacting visual tasks |

5000 |

10000 |

| Performance of exceptional visual tasks of extremely low contrast and small size |

10000 |

10000 |

Factors Influencing Lighting Needs

Task Complexity: Tasks requiring fine detail or prolonged focus necessitate higher illuminance levels to reduce eye strain and maintain accuracy.

Age of Occupants: As individuals age, their eyes require more light to perform the same tasks. A 60-year-old may need up to twice as much light as a 20-year-old, highlighting the importance of adjustable lighting solutions.

Natural Light Integration: Incorporating daylight can enhance mood and reduce energy consumption. However, it’s crucial to manage glare and ensure consistent lighting levels throughout the workspace.

Office Layout and Surface Reflectance: The arrangement of workstations and the color of walls and furniture affect light distribution. Lighter surfaces reflect more light, potentially reducing the need for artificial lighting.

Strategies for Effective Office Lighting

Use of LED Technology: LEDs offer energy efficiency, longevity, and the ability to fine-tune color temperature and brightness, making them ideal for office settings. LED strips or linear LED fixtures are the recommended lighting systems for effective office lighting.

Layered Lighting Approach: Implement a combination of ambient, task, and accent lighting to create a balanced and flexible lighting environment.

Personal Control: Providing employees with control over their immediate lighting conditions can enhance comfort and productivity.

Regular Maintenance: Ensure that lighting fixtures are clean and functioning correctly to maintain optimal light levels.

Optimal office lighting is a blend of science and design, tailored to the specific needs of tasks and occupants. By adhering to recommended illuminance levels and considering factors such as task complexity, occupant age, and natural light integration, organizations can create environments that not only illuminate but also inspire.

LED Strips & Modules for office lighting, made in Germany with the latest technology

Our cutting-edge, high quality, and top-performance LED solutions can be customized online to perfectly match office lighting requirements.

LED Strips for arhitectural lighting, up to 2000 lumens per meter (600lm per foot)

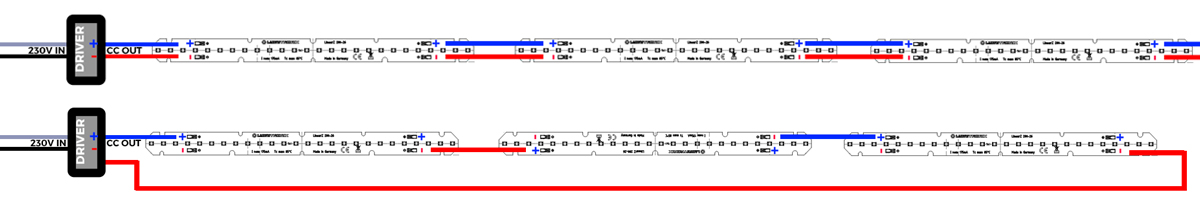

The 3-channel LumiBar can create dynamic lighting effects with white or color Nichia LEDs, suitable for ambient lighting. With the MultiBar LED system, installation is made easy and very affordable, thanks to the plug & play system.

112 x Nichia 757 LED, up to 2000 lm / channel

280x20 mm LED strip

White & Color LEDs

Up to 2000 lm/m from Nichia 757 Series LEDs

500x10 mm LED strip, Plug & Play System

White LEDs 1800-7800K, CRI80-99

24V Constant Voltage

Linear LED Strips & Modules for general lighting, up to 4000 lumens per meter or 1200 lm/foot

Our range of customizable MultiBar or LumiFlex LED strips feature Nichia LEDs that deliver the higher light output required for general lighting.

Up to 3000 lm/m from Nichia 757 Series LEDs

500x10 mm Rigid LED strip

White LEDs 1800-7800K, CRI80-99

24V Constant Voltage

Up to 4000 lm/m from Nichia 757 Series LEDs

White 1800-7800K, CRI80-99

12/24/48V Constant Voltage

Optional IP67 Waterproof System

LED Strips for Commercial Lighting, up to 10000 lumens per meter (3000 lm/foot)

The MaxLine or LumiBar LED strips feature tightly spaced Nichia LEDs that provide a very high luminous flux for task oriented office lighting.

Up to 10000 lm/m from Nichia 757 Series LEDs

280x16 mm LED strip

White LEDs 1800-7800K, CRI80-99

Constant Current & 24V Constant Voltage

Up to 10000 lm/m from Nichia 757 Series LEDs

Many sizes and LED densities available

Flexible & Rigid PCB options

Constant Current design for maximum efficacy

Read more about recommended lighting levels for the home in our blog article.