Nichia Vitasolis, Enhanced White LEDs for Human Centric Lighting (HCL)

- By Ledrise Led Professional

- Mar 8, 2021

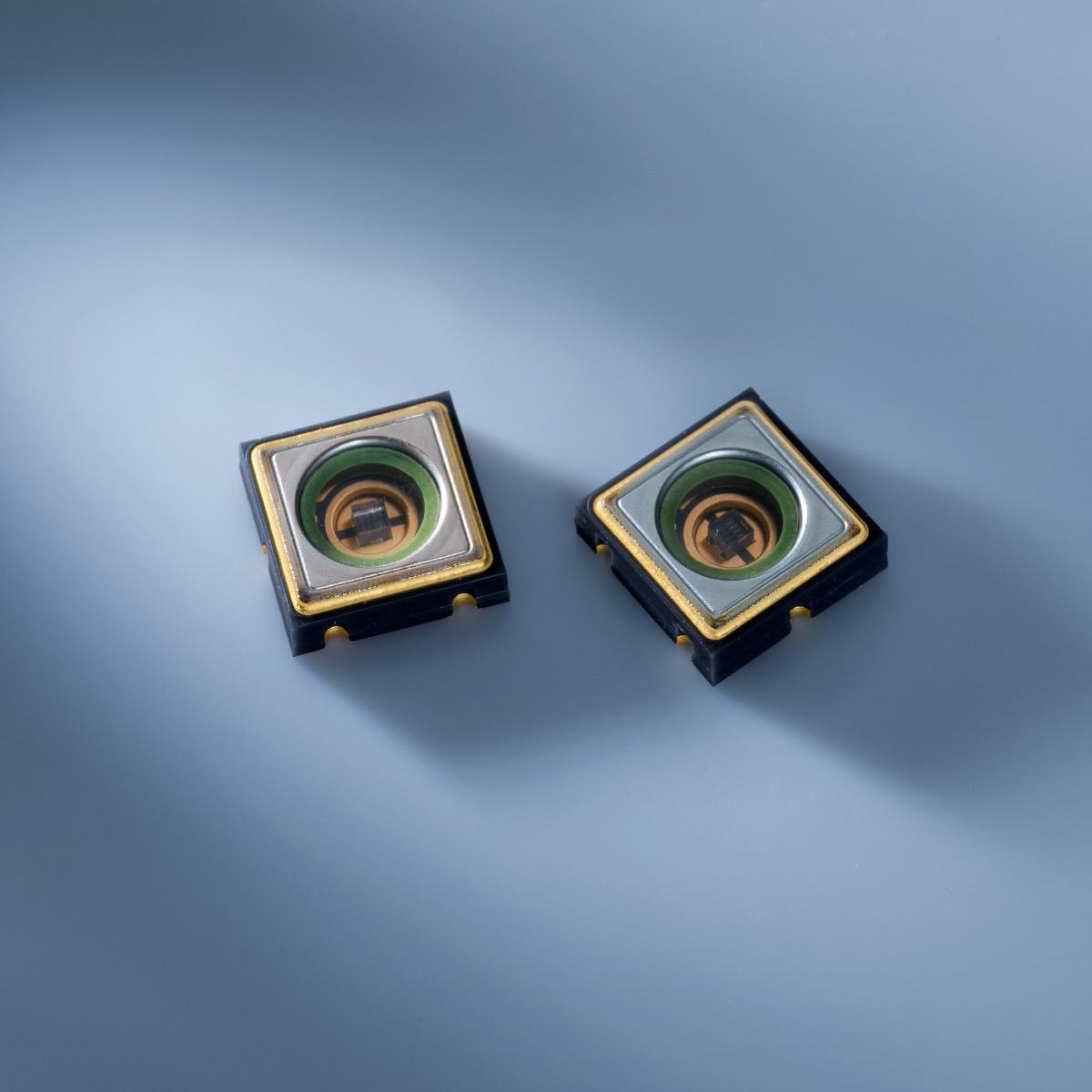

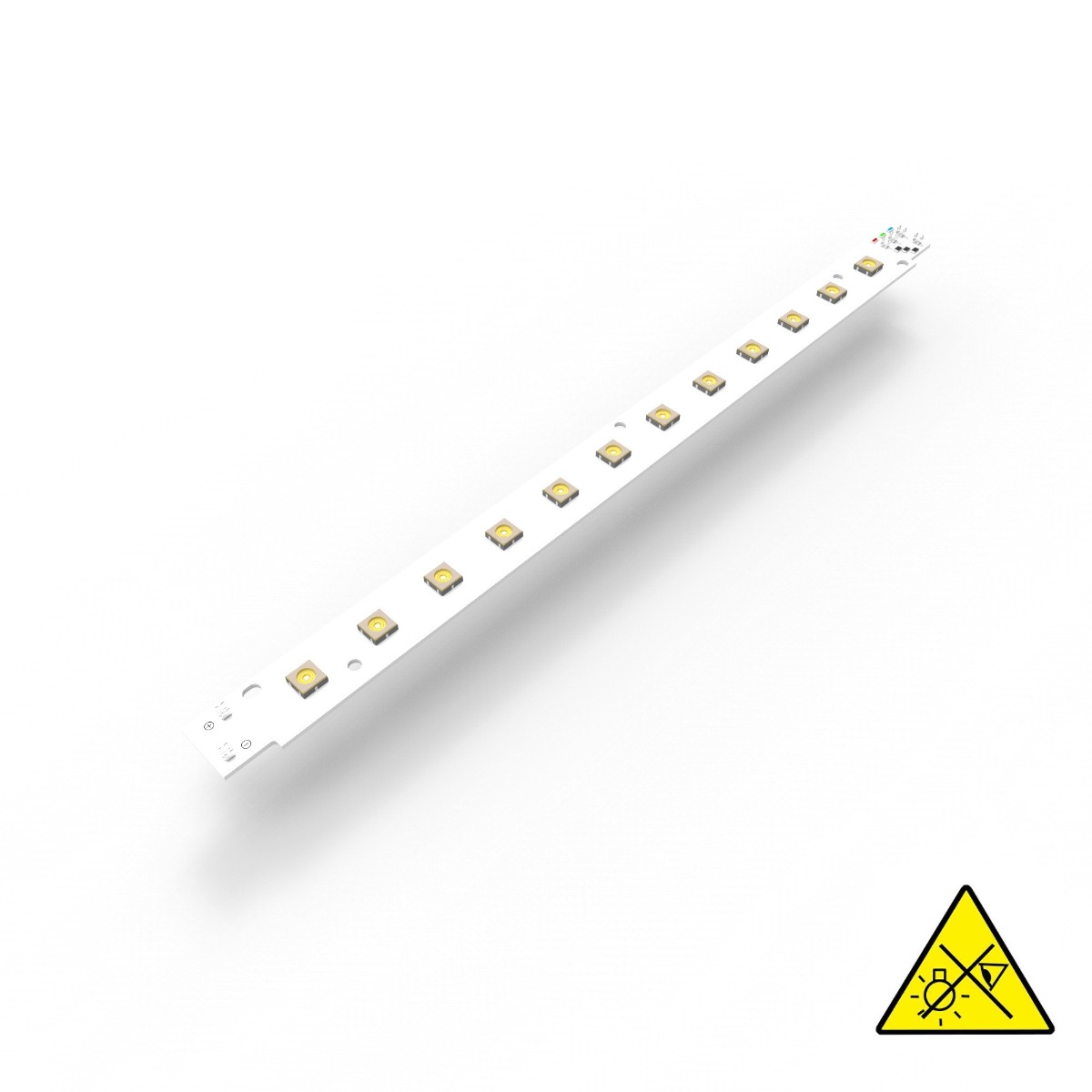

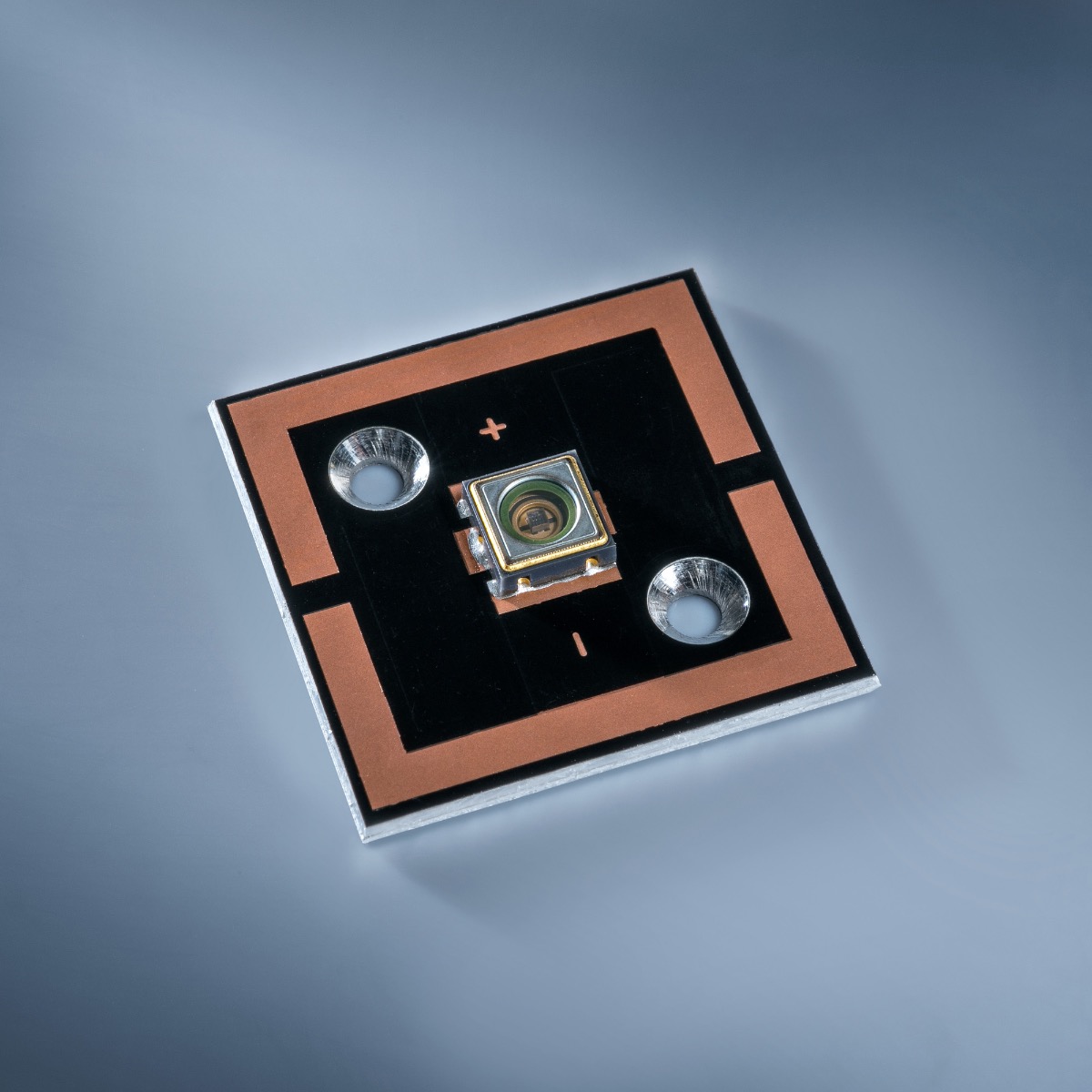

The new Vitasolis™ technology from Nichia are LED light sources with spectrum meant to stimulate activity.

This development in based on recent research that has revealed in detail the relationship between light and human behavior. Humans can recognize the brightness and color of light while human circadian rhythms can be affected by different wavelengths, especially the blue-green area. For example, lighting has an effect on the level of activity throughout the day, including wake up in the morning, daytime activities, and nighttime sleep aids.

Vitasolis has a very natural white light and its spectrum contains more energy in the blue-green region, which helps control the human circadian rhythm. The spectral distribution of Vitasolis clearly illuminates the object while maintaining high light efficiency.