Chip Scale Packaged (Flip Chip) LEDs with small size and high optical density

- By Ledrise Led Professional

- Sep 14, 2020

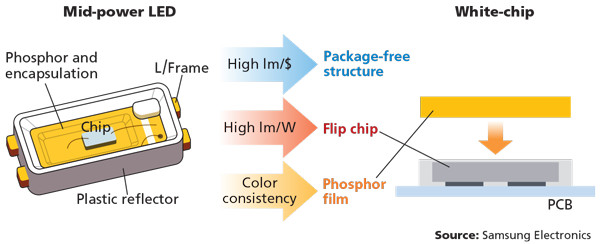

The development of Chip Scale Packaged (Flip Chip or CSP) LEDs is a lighting innovation with several advantages: no substrate, solderless cabling, small size and high optical density.

Chip Scale Package LEDs (CSP) are light sources with all components integrated. This feature does not require soldered wire connections and reduces thermal resistance, the heat transfer path, and potential sources of damage.

A standard light emitting diode (LED) is made of two key parts, the LED chip, which emits the light, and the LED package that focuses it. The package also has the purpose to facilitate mounting in lighting products and dissipates the heat to the heat sink.

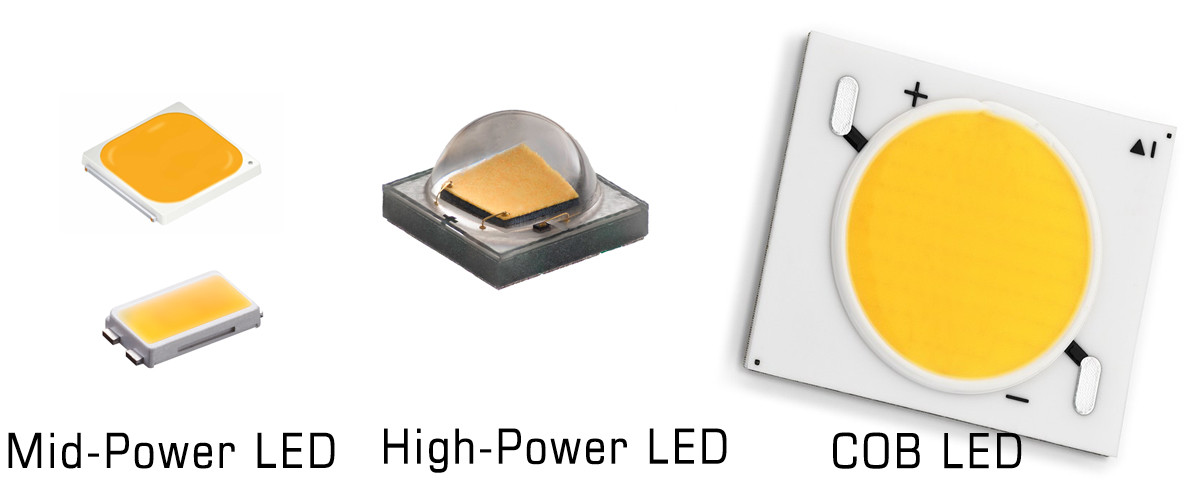

Common examples of packaged LED are those with power from 0.2 Watt or less (Mid-Power LED), 10 Watt or less (High-Power LED) or 2 to 50 Watt for Chip on Board LEDs (COB).

CSP LEDS are compact, one part devices.

If we look at a packaged LED as the automobile with the LED chip of its engine, then a CSP LED is an engine on wheels, with minimal bodywork or other components.

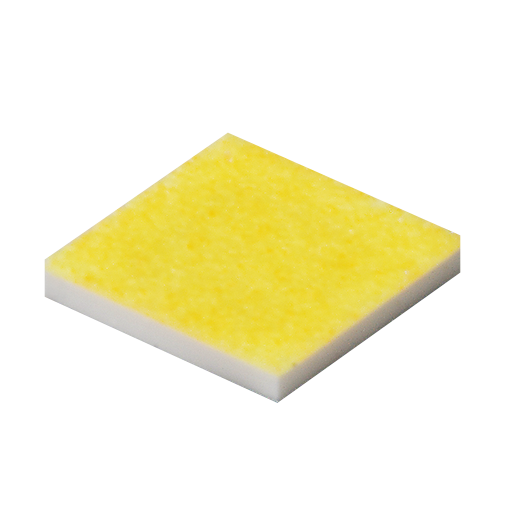

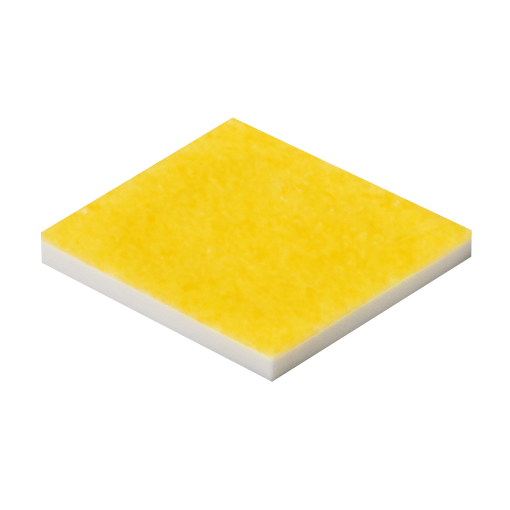

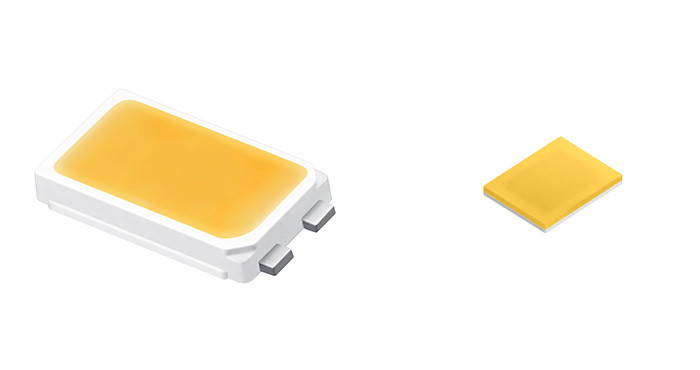

A mid-power LED package (left) compared to CSP LED (right). Except the LED chip, the yellow phosphor and the connection pads all other parts have been removed. This process leads to a significant reduction of the scale, leading to further miniaturization of LED-based lighting.

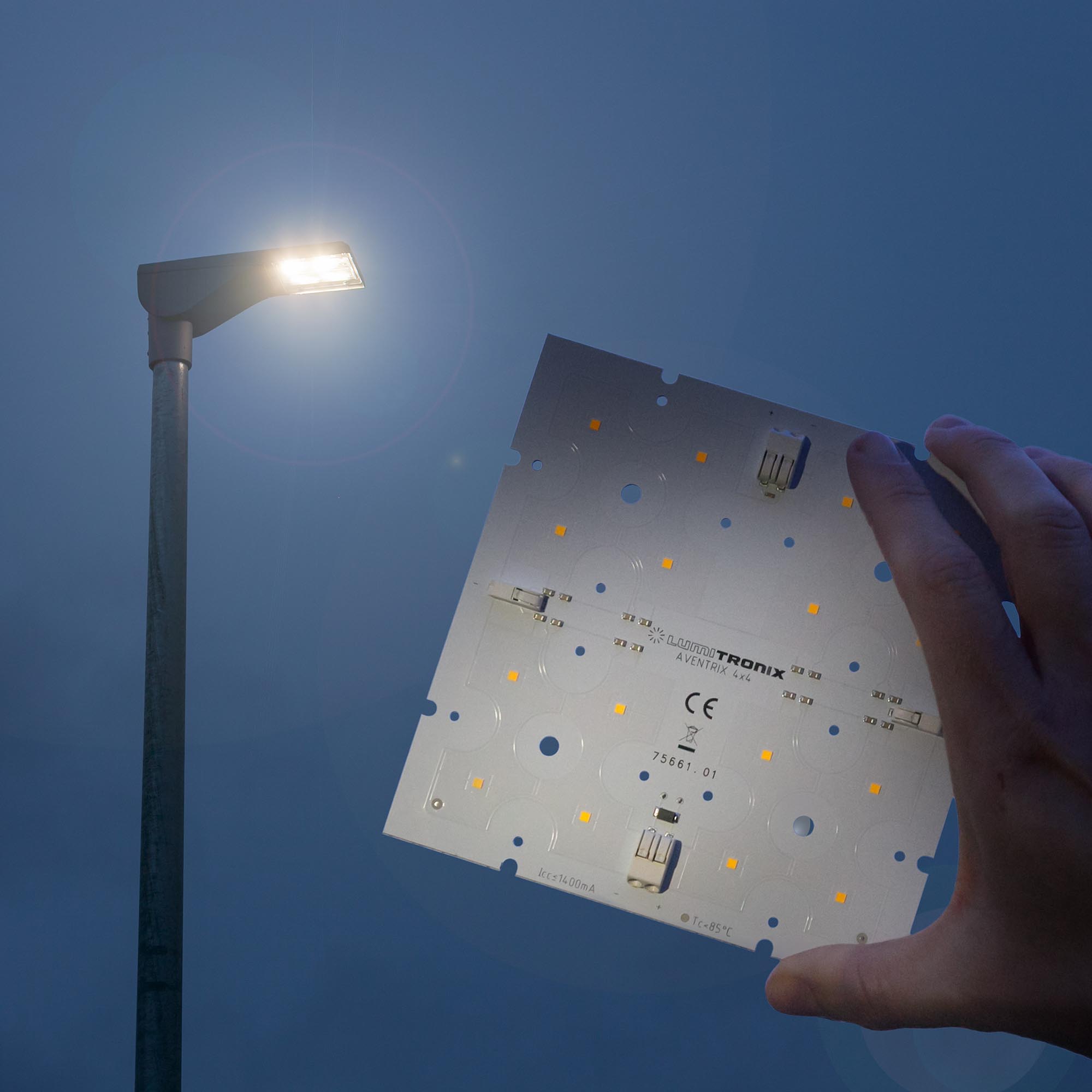

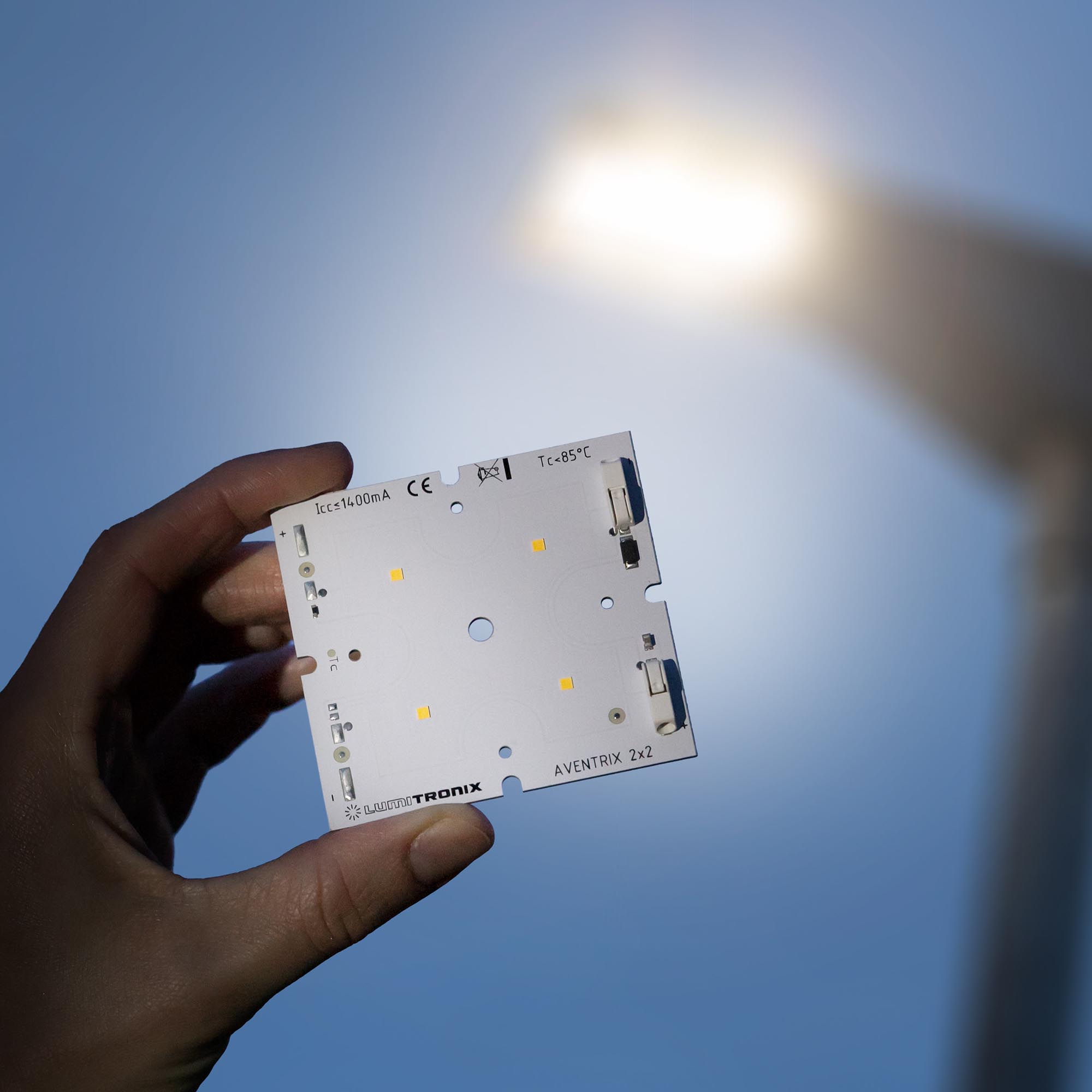

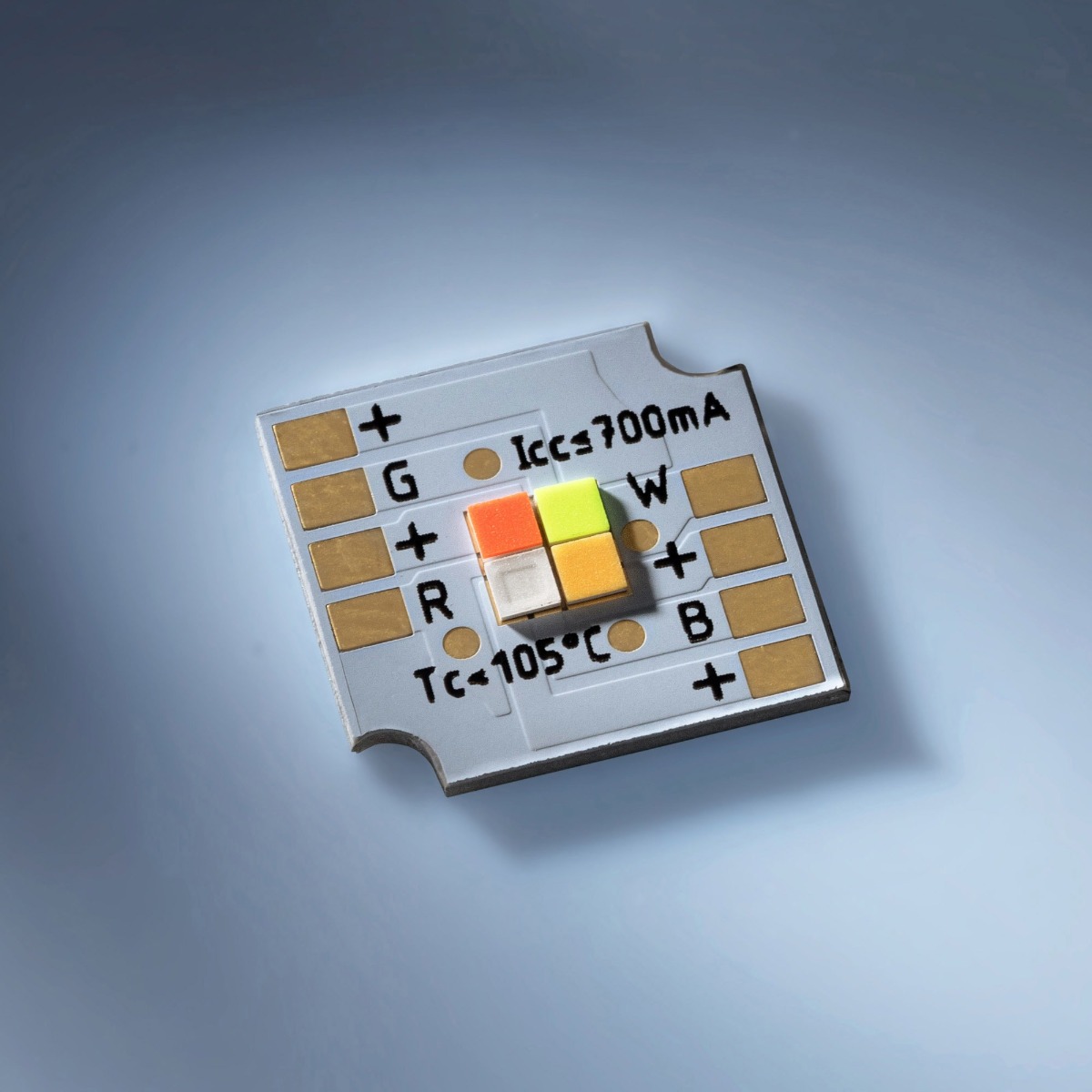

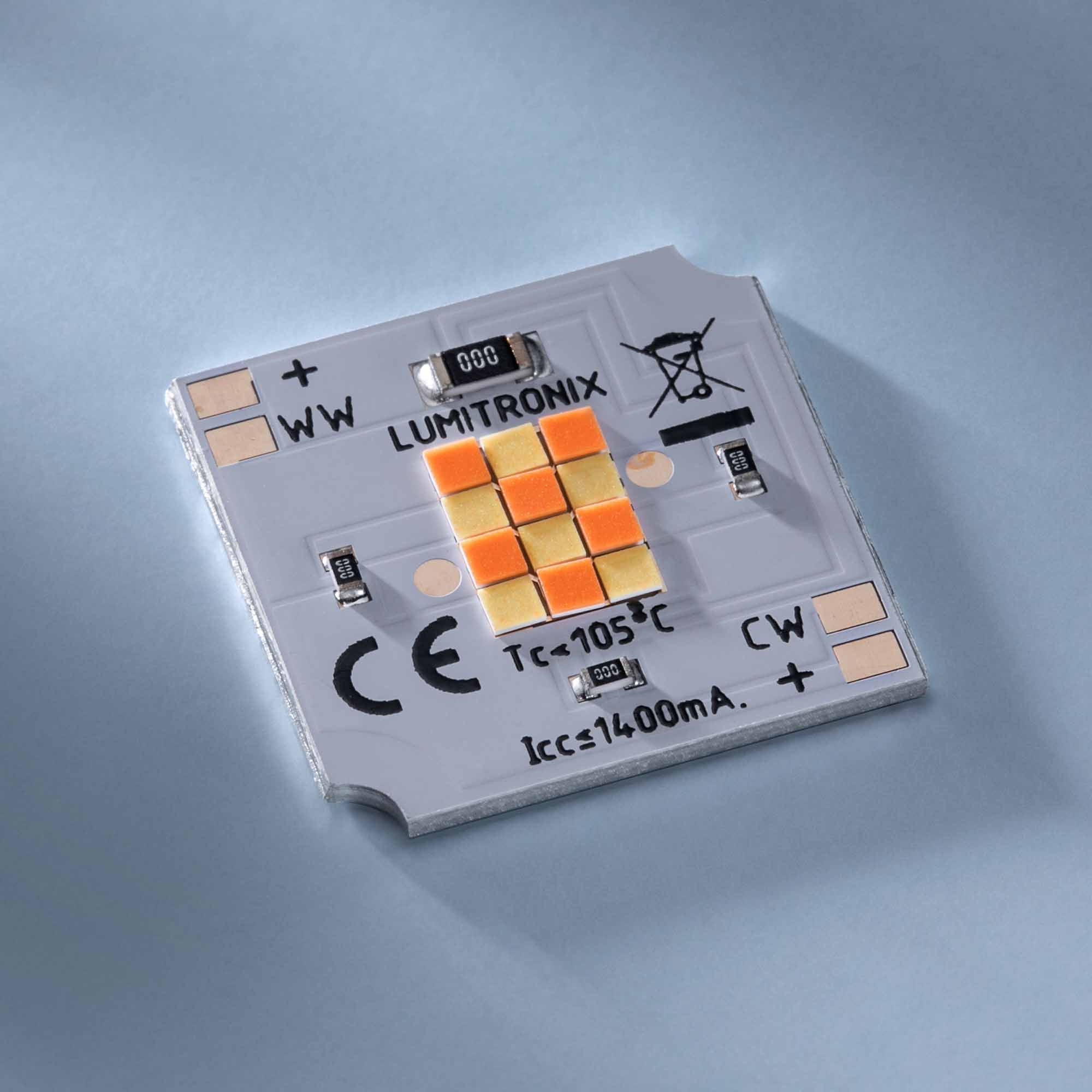

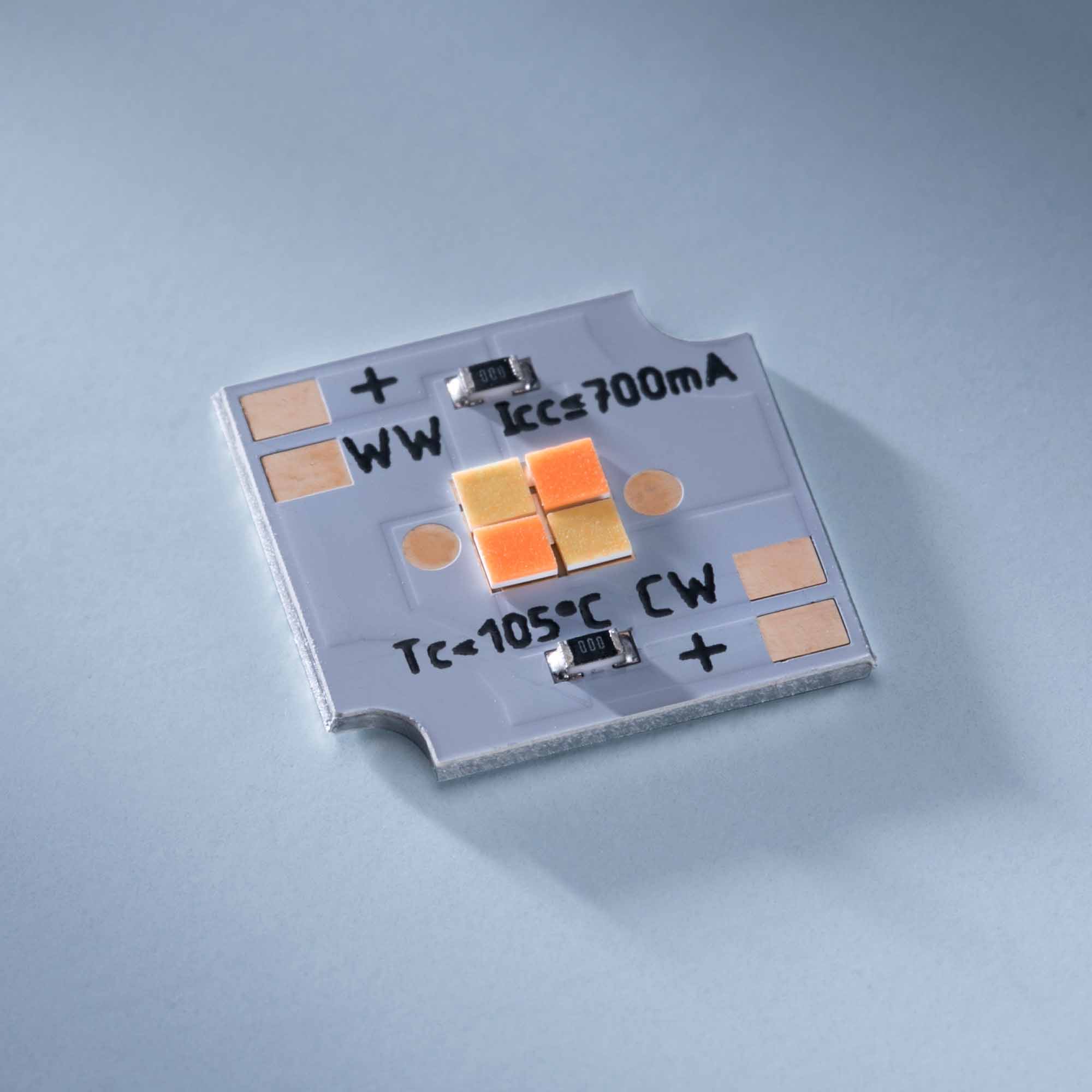

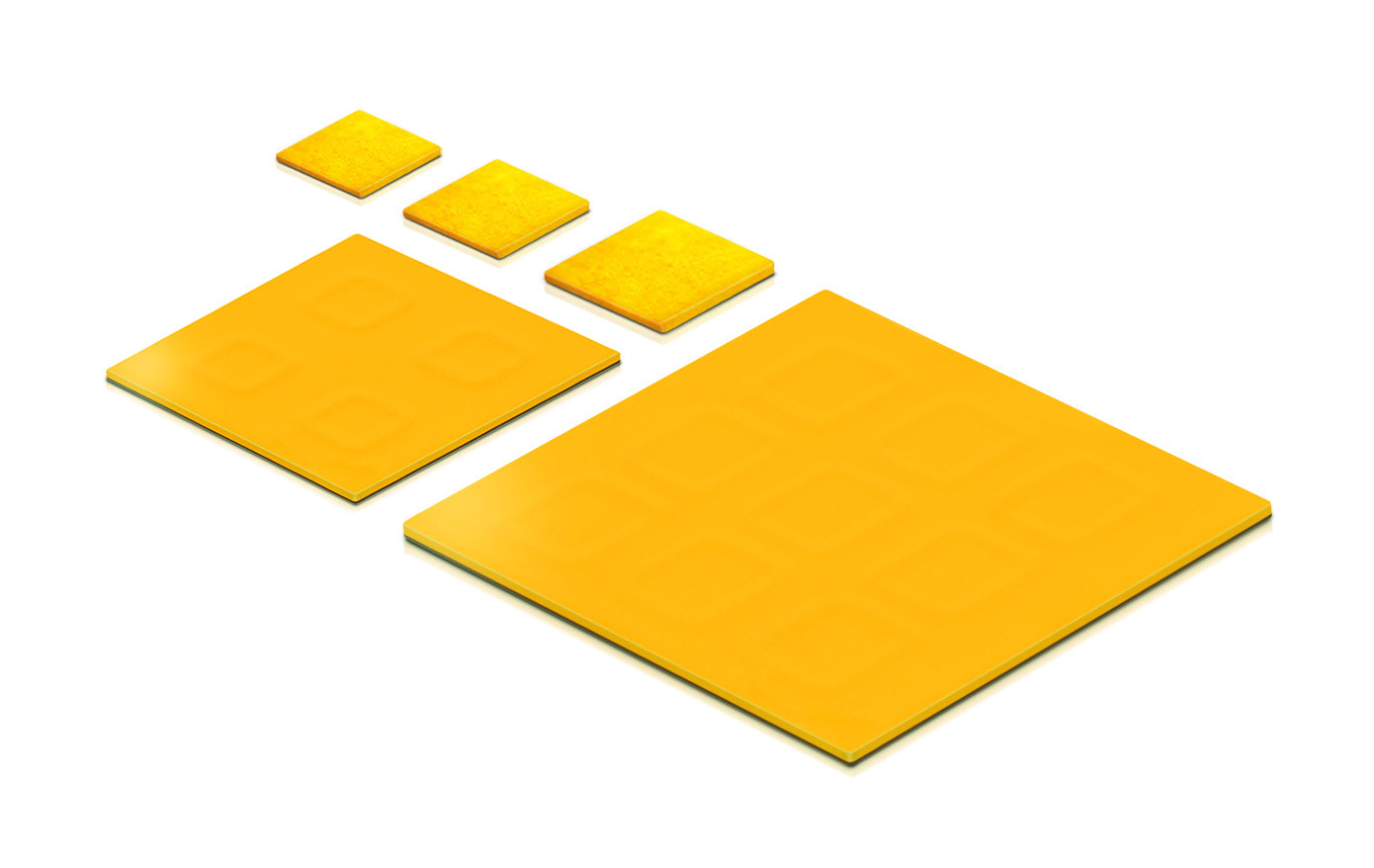

Below, some examples of Samsung CSP LEDs, with different single variations and two array types (2x2 and 3x3).

This bare-bones approach to LED structure has two goals:

- lower cost

- more efficient heat transfer

This can result in a CSP LED fixture with lower price and a slimmer design compared with one that uses a packaged LED.

A CSP LED also has by default a wider viewing angle, of up to 180 degrees because the phosphor is applied on the sides too (see image below). This can be very important advantage for applications such as backlight modules, replacement of traditional form factor lamps and tubes.

CSP is ideal for applications such as LED strips with continuous light, LED backlighting, street lighting, ultra-wide angle modules, spotlights.

Some LED lighting manufacturers use CSP chips to replicate the size and position of the tungsten filament in halogen lamps to produce beam patterns similar to those of halogen lamps.

We can summarize the advantages of CSP LEDs:

- Better heat dissipation

- Higher lumen density

- No holder and alloy wire, fewer production processes, more reliability

- More flexible

Leading companies such as Nichia, Osram, Samsung, Seoul Semiconductor or Cree manufacture CSP LEDs, LED chips and packaged LEDs.

Small manufacturers usually buy LED chips and assemble them into packaged LEDs. This explains the enormous, sometimes confusing differences in specification, performance and quality of the packed LEDs. The properties of packaged LEDs are defined by both the design and production of chips and packages.

At Ledrise you will find the CSP LEDs from Nichia in emitter form, single LED module format and as multi-LED arrays: