Demystifying LED Lifetimes: From Light Bulb to LED

- By Ledrise Led Professional

- Jul 23, 2020

Understanding the product lifetime of a light source is essential when making a decision on which lighting option is best for your needs. Traditional incandescent light bulbs and modern LED lights have different lifetimes, and understanding these can help you make an informed choice.

This article aims to explain the concept of product lifetime for incandescent light bulbs and LED lights, as well as discuss the methods used to measure and project the lifetime of LEDs.

- Defining Product Lifetime: Light Bulb vs LED

Incandescent light bulbs have a typical product lifetime of 1,000 hours. When the bulb reaches the end of its life, it ceases to emit light due to the filament breaking down, often accompanied by a spark or pop.

LEDs, on the other hand, use a different definition for product life. As the only light source that loses brightness over time, LEDs can lose up to 90% of their initial flux, although they may still emit visible light even after decades. For example, a Nichia LED with a typical product lifetime of 60,000 hours can continue to emit light well beyond its rated life, possibly even after 200,000 hours.

LED lifetime is the time interval during which the product can still serve its intended purpose. The point at which an LED has only 70% of its initial brightness is considered its product lifetime, known as the L70 lifetime. This definition is endorsed by all well-known luminaire manufacturers and sellers.

- Measuring LED Lifetime: The IES LM80 Standard

With LEDs like the Nichia 757 series boasting lifetimes of over 60,000 hours, observing the product's brightness after such a long time is impractical. To address this challenge, the industry has developed the IES LM80-80-2008 measurement standard and the IES TM21-2011 standard for projecting long-term lumen maintenance of LED light sources.

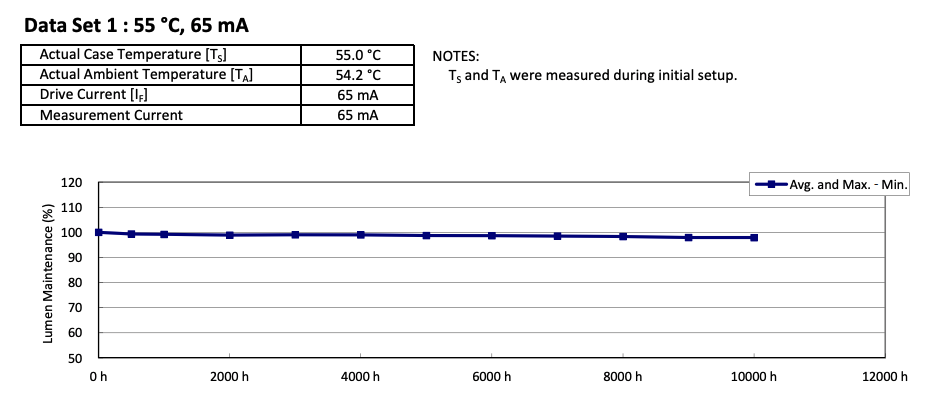

IES LM80, or "Measuring Lumen Maintenance of LED Light Sources," is the industry standard method for testing LEDs to measure their loss of brightness over time, known as lumen depreciation. This method requires observing LEDs of the same type, grouped in batches operating at different currents and temperatures, for up to 6,000 to 10,000 hours. The luminous flux of these LEDs is measured at 1,000-hour intervals, and the results are plotted on a graph showing the LM80 degradation curve of the LED light source.

Below, the graph of the degradation curve up to 10,000 hours for a Nichia 757 LED at 55C, 65mA:

The LM80 test is a Department of Energy (DOE)-approved method for measuring lumen depreciation of solid-state light sources, arrays, and modules. The Illuminating Engineering Society (IES) and the DOE Solid State Lighting Standards Development Group collaborated to create the LM80 test criteria.

- Projecting LED Lifetime: The IES TM21 Standard

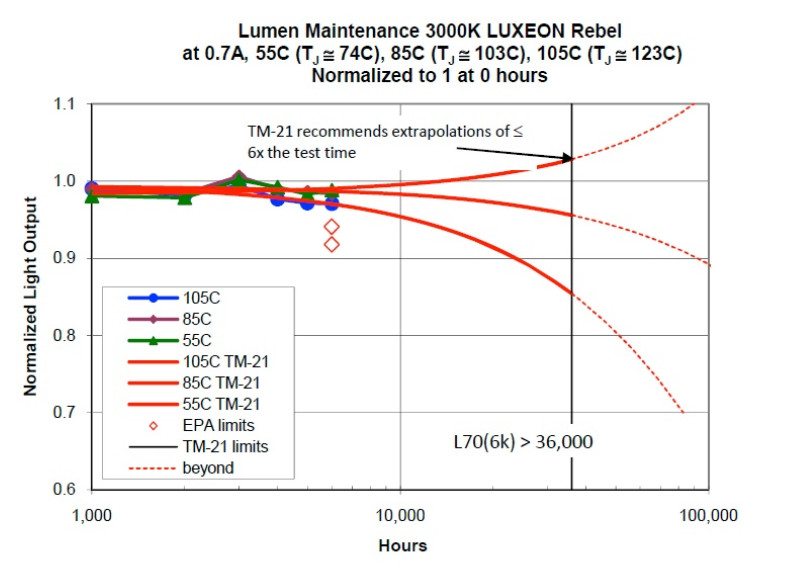

IES TM21 is designed to project the long-term lumen maintenance (brightness loss) of LED light sources. It provides a method for using the measured LM80 data to project future LED lifetimes. In simpler terms, an exponential curve is plotted between the 1,000-hour test points on a graph, showing lumen maintenance from 100% to 70%.

The condition for using TM21 projections is that they can be made for a time interval only six times longer than the LM80 measurement. If the LM80 measurement duration is only 6,000 hours, the maximum life that can be projected is 36,000 hours, specified as L70 (6K) >36,000 hours. If 10,000 hours of testing are performed, it would be L70 (10K) >60,000 hours.

The LED service life, according to LM80 and T21, consists of two parts: the actual testing with LM80 and the six-fold test time projection with TM21.

Example LED:

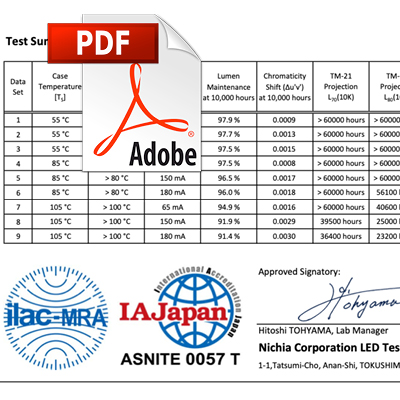

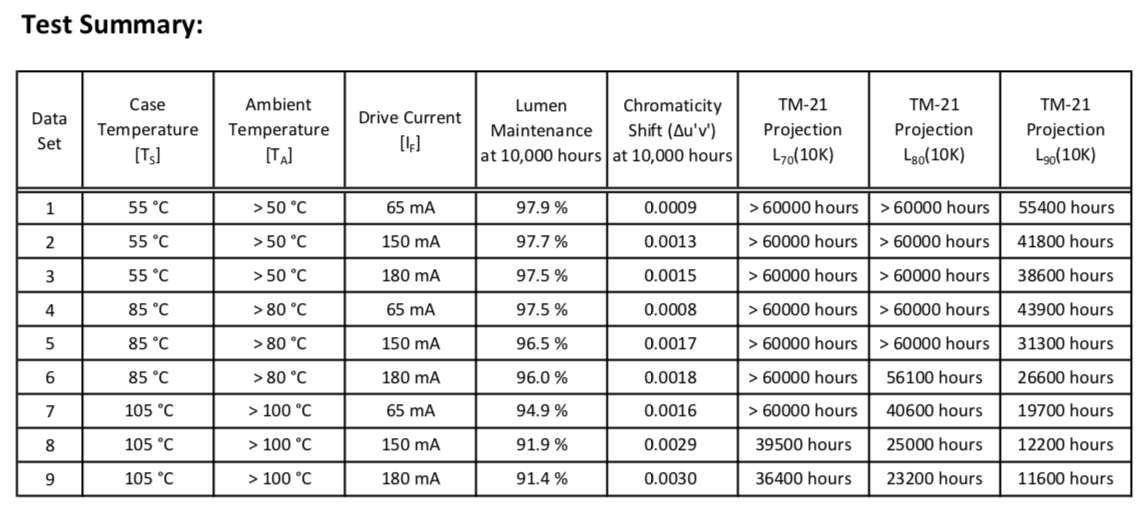

Example: Nichia LED, with data sets of different case, ambient and drive current values

- Factors Affecting LED Lifetime

Several factors can impact the lifetime of an LED, including:

- Operating temperature: LEDs are sensitive to heat, and high operating temperatures can lead to a shorter lifespan. Efficient heat management is essential for optimal LED performance and longevity.

- Driving current: Higher driving currents can increase the light output but may also lead to a reduced LED lifetime. It is crucial to operate LEDs within the recommended current levels specified by the manufacturer.

- Quality of materials and design: High-quality LEDs from reputable manufacturers, such as Nichia or Cree, tend to have better lifetimes and performance compared to low-quality alternatives.

- Making Informed Lighting Decisions

Understanding the concept of product lifetime for incandescent light bulbs and LEDs is vital when selecting the best lighting solution for your needs. LEDs offer significant advantages over traditional light bulbs, such as energy efficiency, longer lifetimes, and reduced maintenance costs. However, it is essential to consider factors such as operating temperature, driving current, and the quality of materials when choosing an LED product.

By familiarizing yourself with the industry standards for measuring and projecting LED lifetimes (IES LM80 and TM21), you can make informed decisions on the most suitable LED products for your application.

In conclusion, LEDs are a promising alternative to traditional incandescent light bulbs due to their energy efficiency and longer lifetimes. By understanding the factors that affect LED lifetime and the industry standards for measuring and projecting their performance, you can make informed decisions on the best lighting solutions for your needs. Always opt for high-quality LED products from reputable manufacturers to ensure optimal performance and longevity.

An example of a L80 & TM21 lifetime for Nichia LED test can be downloaded below:

At Ledrise we use only LEDs that have comprehensive and trustworthy LM80 and TM21 reports.