Heat management of LEDs

- By Ledrise Led Professional

- Dec 15, 2020

Each of the LED packages has a thermal resistance of 5°C/W (Rled). The LEDs are placed on aluminum board and heat sink with a total thermal resistance of 15°C/W (Rhs)

At specific points in the thermal circuit (equivalent to the data network) temperature values are defined. For the array in our example the below are of interest:

- Tjunction (Tj)

- Tambient (Ta)

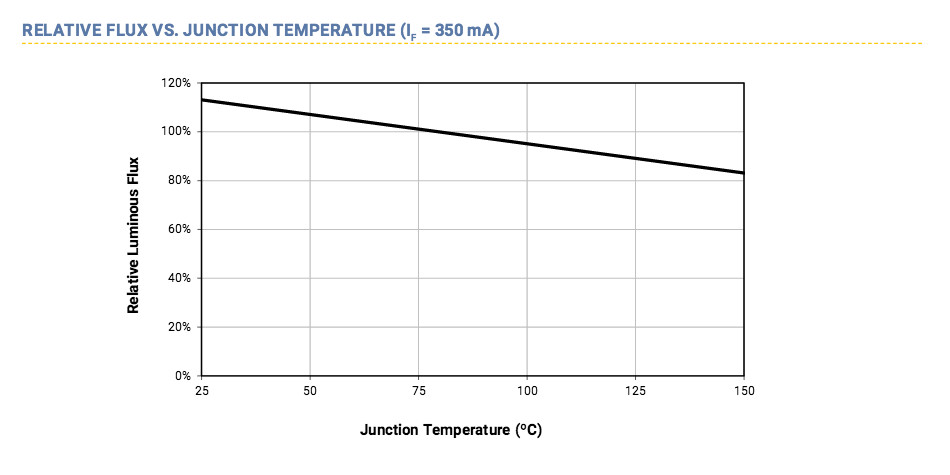

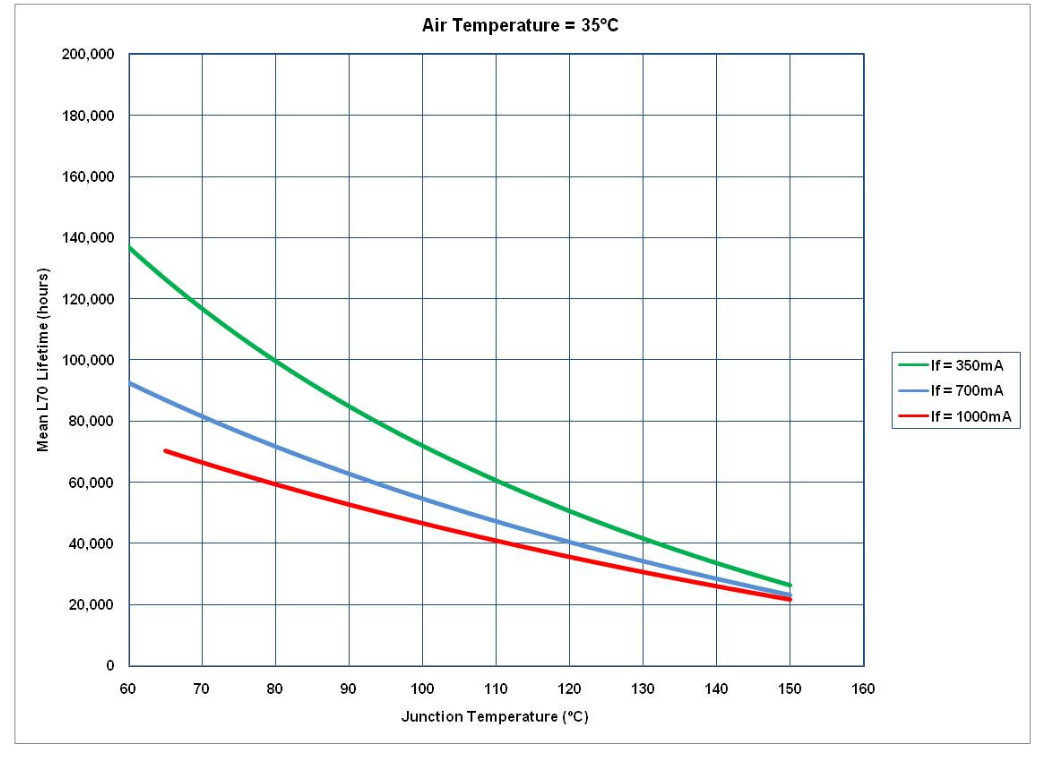

With these temperature values we can discover how a LED will perform (Relative Luminous Flux) and what lifetime will it have (L70 Lifetime). Both depend on the temperature inside the LED, called junction temperature, a relationship usually represented in graphs as the ones below.

Let's say we install the array in a closed luminaire that works in a hot environment. This can mean an ambient temperature of 60 °C (Ta). We then calculate the connection temperature (Tj) to be used with the diagrams above.

Tj= Ta + Ptotal * Rhs + Pled *Rled

Tj = 60 °C + 4 W * 15°C/W + 1 W*5°C

Tj = 60 °C + 60 °C + 60 °C + 5°C = 125°C = 125°C = 125°C

Each LED in the array has a connection temperature of 125°C.

This information shows us the gap between actual and advertised performance and longevity.

If the LED array manufacturer claims that each LED has 100 lumens and 80,000 L70 lifetime at an ambient temperature of 25°C, we can easily determine that there is a gap. With the above calculations and diagrams, the realistic values for each LED are 90 lumens and 30,000 hours L70 lifetime.

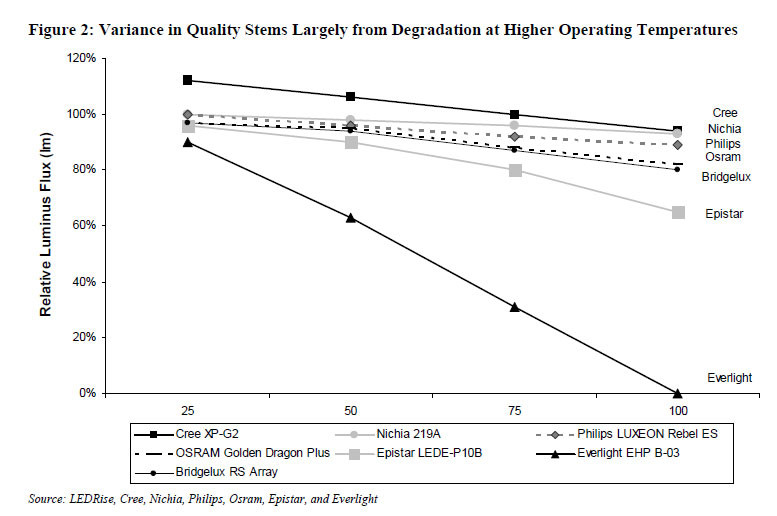

The picture's not always so good. There are many cases where the gap between real and advertised is huge.

Below you will find two examples.

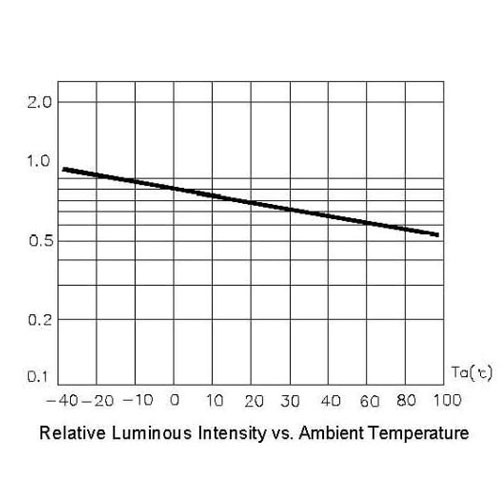

Figure 1: A diagram of a random supplier on Alibaba. At 60 °C we see a 40% drop in LED power. Although no lifetime data was available, we could safely assume that the life of the L70 would not exceed a few thousand hours.

Figure 2: A graph compiled from data sheets of several manufacturers, with the specific LED models mentioned at the bottom.

In conclusion, we should always consider the ambient temperature relevant to our project, how good is the LED product at heat management and how the actual junction temperature impacts LED performance and lifetime.

There should also be an understating that a low price usually means poor LED performance at high temperature, inefficient heat management and absent, incomplete or misleading data about the performance and lifetime of the product outside of a cooled testing chamber.

With the above in mind we have selected the Nichia 757G LEDs as the LED of choice for most our LED strips. The proprietary Nichia design of the 757G has the best resistance to high temperature on the market and thus ensures the best performance with the easiest thermal management.